- Creating a self-sustaining, high-performance innovation engine is the goal many companies adopt PLM systems to accomplish. Gaining greater customer insights from CRM systems and breaking down internal barriers with real-time ERP integration is revolutionizing manufacturing today.

- By 2025, 75% of manufacturers will move from traditional stand-alone applications to digital PLM platforms that scale quickly, accelerating new product development cycles with greater customer and product intelligence according to a recent survey by Gartner.

- Controlling costs, increasing compliance & quality levels, reducing time to market, improving traceability and enabling greater supply chain visibility are the five most valuable benefits of integrating PLM, CRP and ERP systems. The more integrated a PLM system, the greater the potential it has to attain between a 20 to 40% increase in revenue.

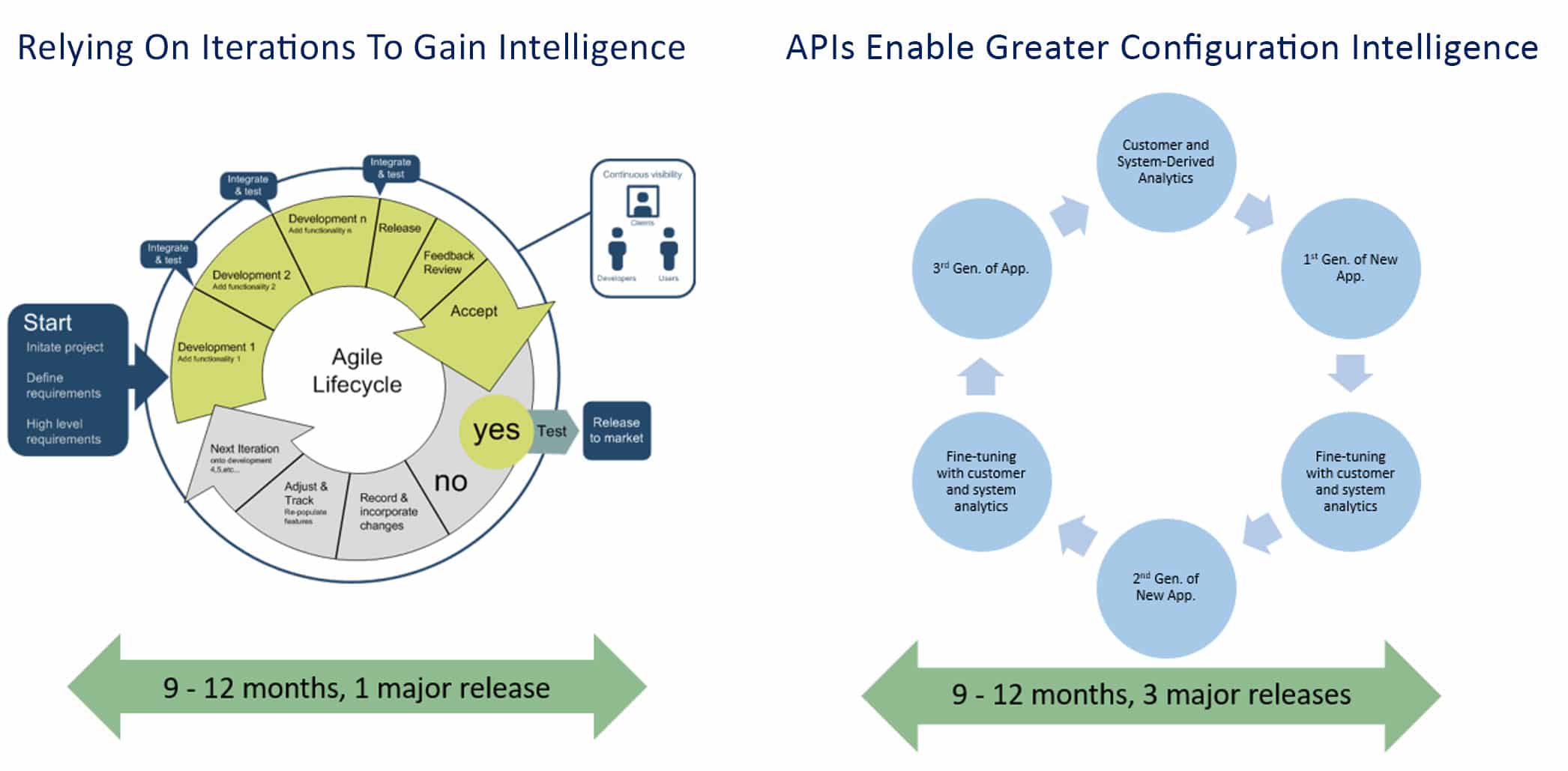

The greatest challenge many manufacturers face is keeping a fresh pipeline of new product ideas moving. Growing, nurturing and transforming the pipeline into profit is why integrating PLM platforms and applications with CRM and ERP systems is critical. And it’s more than just getting an adapter or connector created by a system integrator or doing the work internally by an IT team. What’s often needed is an Application Programming Interface (API) approach to integrating systems together, so data is exchanged in real-time. The goal is to create new levels of customer and configuration intelligence. Taking an API approach can lead to up to 3 new product releases a year. Taking a more traditional approach to integration with ETL and other legacy technologies slow down the new product pipeline and release schedule.