Be Prepared to Handle Unexpected Global Supply Chain Disruptions

Adapt to part shortages and delivery delays with Configit Ace®

With global supply chains becoming more sensitive to disruptions, manufacturers are seeking solutions that can help them to quickly mitigate global supply chain disruptions.

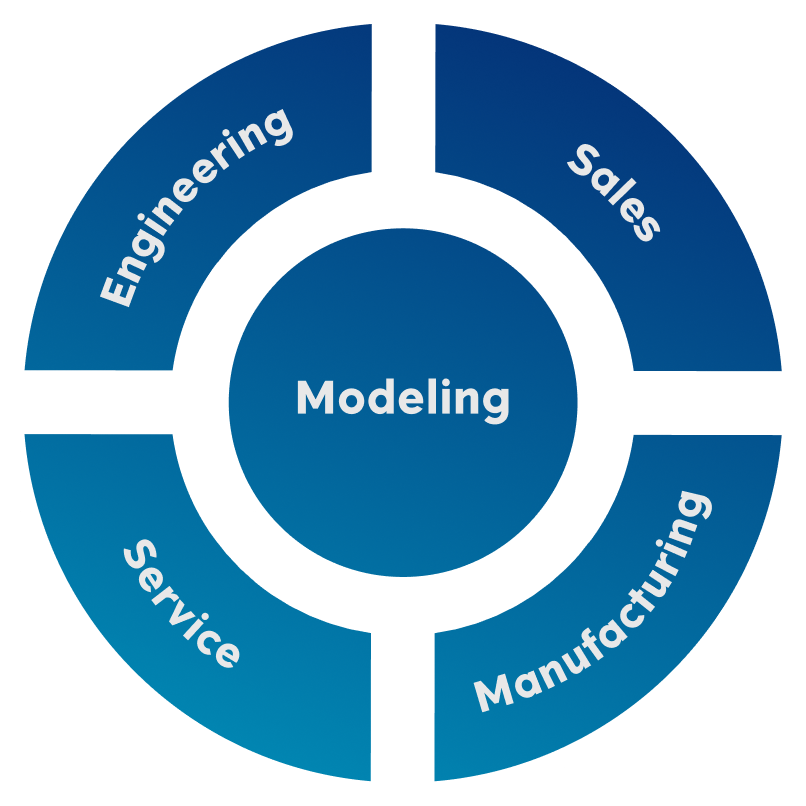

Using a Configuration Lifecycle Management (CLM) approach, it is possible for manufacturers of customizable products to model alternative supply chain strategies for critical materials, components and modules. This enables manufacturers to quickly, and centrally, enact alternatives in the event of a disruption as well as establish an overview of customers affected.

This approach enables manufacturers to manage various types of global supply chain disruptions, quickly provide alternatives, and keep valued customers informed throughout.

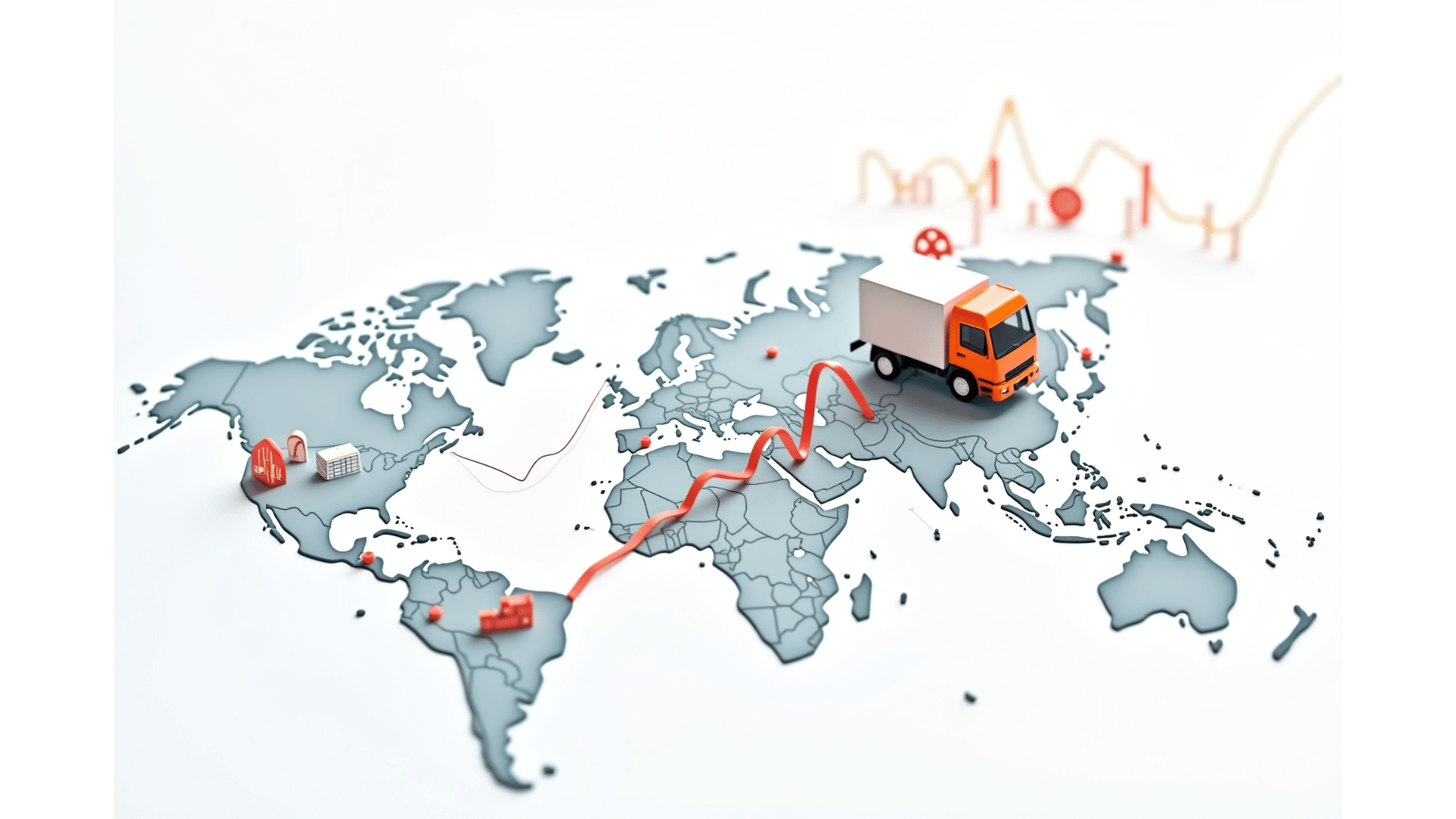

The Growing Volatility of Supply Chain Risk

Globalization has contributed to highly complex supply chains that are fine-tuned for precise and dependable delivery. Because of this, B2B and B2C customers have become accustomed to reliable delivery and have low tolerance for delays.

Unfortunately, the last decade has shown how vulnerable supply chains are to disruptions. The Suez Canal closure, Fukushima, COVID, Somali pirates, and fluctuating economic and geopolitical tariffs are all examples of unforeseen disruptions that have impacted supply chains.

Supply chains have become so complicated that analysts and researchers struggle to accurately map the full extent of increasingly global supply chains for specific products. Current tariff rates across the globe complicate the issue further as it is difficult to calculate the total impact of tariffs on the supply chain in advance, especially if tariffs change often.

The economic impact of these disruptions has highlighted the need for contingencies and solutions that can be deployed when the unexpected occurs.

Build Resilience: Plan for Unforeseen Global Supply Chain Disruptions

In a typical manufacturing process, engineers define the parts needed to build a product in engineering BOMs. These are then refined in local factory manufacturing BOMs to specify which vendors and product numbers are needed to deliver the product from that factory. Manufacturing BOMS are commonly managed by ERP or MES systems which can be used to define alternative suppliers and materials.

This process is generally adequate for standard products, as a limited number of pre-defined alternatives need to be established. Issues arise, however, when the same process is used to manage customizable, or configurable, products. Because configurable products can have thousands of engineering, manufacturing, sales and service options, which can be interdependent, making a change in one system, such as the ERP, could have unforeseen consequences as configuration rules in other systems could be violated. A more centralized approach is needed that ensures any changes or alternative solutions are already validated from the beginning.

Pre-validate Alternatives Using a CLM Approach

Using a Configuration Lifecyle Management (CLM) approach, manufacturers can pre-define and pre-validate supply chain options and alternatives in advance in preparation for supply chain shocks and other disruptions, including changing tariff rates that can influence default options offered.

With a CLM approach, manufacturers can:

- Consolidate configuration options and rules from various systems, such as PLM, ERP, MES, CRM and CPQ systems, into a shared product model that is available to all

- Coordinate interdependencies between configuration data from the various systems and identify inconsistencies and gaps that can be rectified in the original systems

- Consume the shared product model in any system via open web-based APIs

- Control what is offered and what has been ordered, delivered and serviced centrally

This approach enables configuration data from multiple systems to be coordinated and validated to identify issues before release to downstream manufacturing, sales and service systems.

Implement a CLM Approach with Configit Ace®

Configit Ace® provides multiple methods for consolidating data from existing systems into a shared product model.

- Configit Ace® Model provides an intuitive product modeling environment where product models can be enhanced with additional options and rules.

- Configit Ace® Verify provides a test and validation environment as well as analysis tools for understanding which options are being offered to customers.

At the heart of Configit Ace® is Configit’s unique Virtual Tabulation® technology that enables all valid configurations to be pre-calculated and validated before release. For highly complex product models this can lead to between 10²⁰ and 10²⁰⁰ valid configurations. With Virtual Tabulation® the compilation of all these valid configurations takes minutes and any inconsistencies or gaps are captured during the compilation process with explanations for how to rectify the issue.

It is this capability that enables validation and verification of product options and rules before release even when they are sourced from multiple systems.

Virtual Tabulation® produces a compact virtual table of valid configurations that can be used to validate whether a configuration is valid or not in milliseconds. It can also be analyzed to understand what exactly is being offered to customers at any time.

Download the Solution Brief: Stay Ahead of Supply Chain Disruptions

Learn how Configit Ace® helps manufacturers predefine alternatives, synchronize configurations across systems, and respond instantly to shocks. Get practical insights and a real-world OEM case study.

Accurate, Real-time Order Visibility

Configit Ace® not only centrally manages what is offered to customers through the shared product model, it also manages product configurations made by customers. When end-user configurations are saved by Configit Ace®, additional meta-data is saved with each configuration to provide traceability and enable analysis as well as linked information. This means that all end-user sales configurations, manufacturing configurations and service configurations are saved and inter-related forming a Digital Configuration Thread.

This central repository of information can be used by manufacturers to understand which open orders, current orders in production and products that need to be serviced are affected by the supply chain shock. This provides an additional layer of information that can complement information available in ERP, CRM and other critical systems in swiftly informing affected customers.

Plan for the Unexpected by Adopting a CLM Approach – Takeaways

- Using Configit Ace® manufacturers can implement a CLM approach and be prepared for the unexpected as much as possible.

- Using a CLM approach provides a shared-source-of-truth that can be examined, adapted, validated and synchronized with downstream systems to manage the supply chain shock as quickly as possible, even if pre-planning is impossible.

Contact Configit to understand how you can prepare for the unexpected.

Get a Configit Ace® Demonstration

Experience first-hand the power of Configit Ace® by scheduling a demo with our experts.

Daniel Joseph Barry is VP of Product Marketing at Configit. Dan Joe has more than 30 years of experience in engineering, sales, marketing, product management and strategy roles within IT and telecom companies.