Reduce Callbacks, Optimize Service, and Accelerate Product Development with Configuration Lifecycle Management (CLM)

Manufacturers using Configuration Lifecycle Management have greater control over their engineering processes by understanding which combinations of parts and features are ordered most so that they can transition to a Configure-to-Order business model.

With less time spent recreating the same or similar configurations from scratch, every time an order is placed, manufacturers can reallocate resources to more profitable tasks such as new product development.

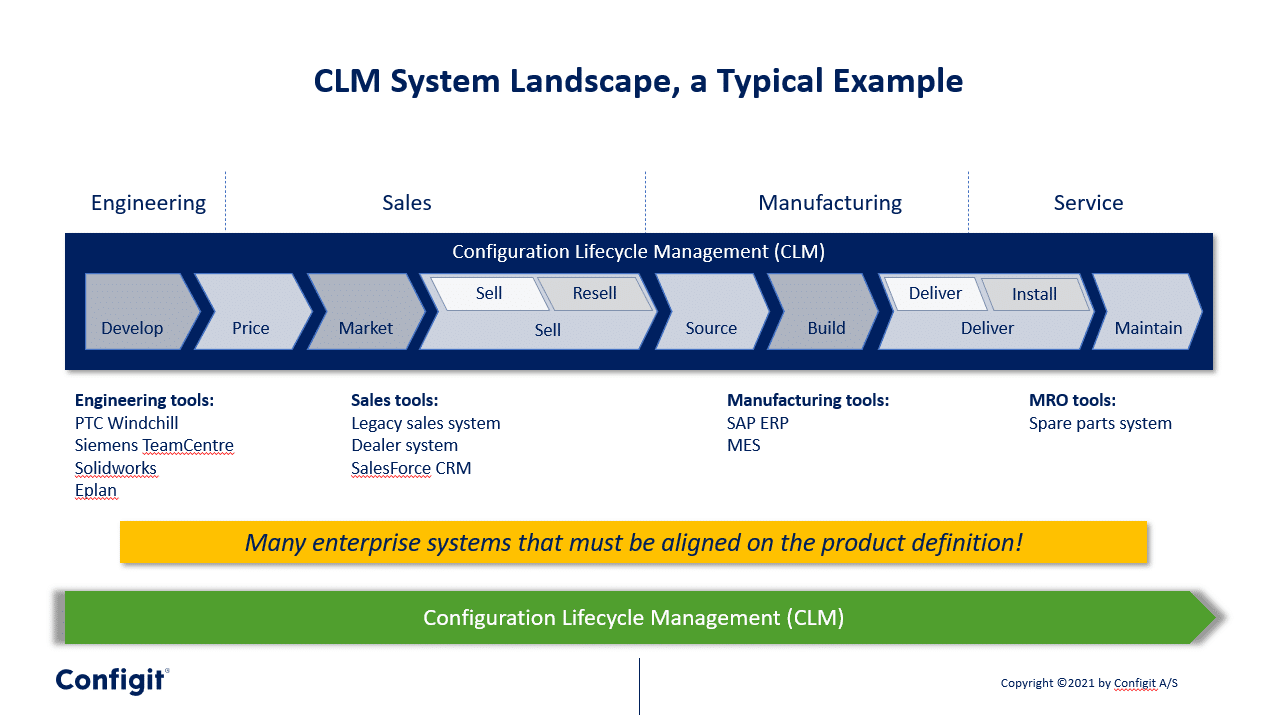

This shared source of truth enabled by CLM provides benefits throughout the organization, not only in Engineering and Manufacturing.

For elevator manufacturers, this means turning their post-sales, service and maintenance functions into a source of revenue rather than a cost center. By having the knowledge of the exact configuration of an elevator or escalator means service calls will be faster (no more arriving with the wrong parts) with significant opportunities to provide information on updating and upgrading existing products.