Closing the Skills Gap:

How CLM Drives Manufacturing Success

The manufacturing landscape is undergoing a significant transformation. Increased competition, evolving customer demands, and a rapidly changing technological landscape are pushing manufacturers to innovate and adapt at an unprecedented pace.

However, these pressures are compounded by a growing workforce shortage, as:

- Seasoned employees retire.

- Skilled labor becomes increasingly difficult to find.

- Too many manufacturing processes are document-driven.

- Disjointed systems and processes relying on experienced employees to interpret and validate information exchanged at each step of the process to ensure alignment.

Using a Configuration Lifecycle Management (CLM) approach, manufacturers can capture and preserve the critical product knowledge and expertise of their experienced employees in a product model where this experience is expressed as ‘rules’ and shared throughout the organization.

This approach allows all to leverage the historical knowledge and experience of every employee, helping to bridge the skills gap by making that knowledge accessible to everyone. Because this knowledge is integrated into the product model, new employees face a less challenging learning curve. Creating this “shared source of truth” for the entire organization also provides a basis for automation and the replacement of inefficient processes that rely on documents.

Discover How CLM Tackles Workforce Challenges in Manufacturing

Many manufacturers rely on disparate systems and manual processes, leading to data silos, inconsistencies, and a lack of visibility. Some organizations can have dozens of PLM or ERP, leading to duplicate, unreliable data. This is where Configuration Lifecycle Management (CLM) comes into play.

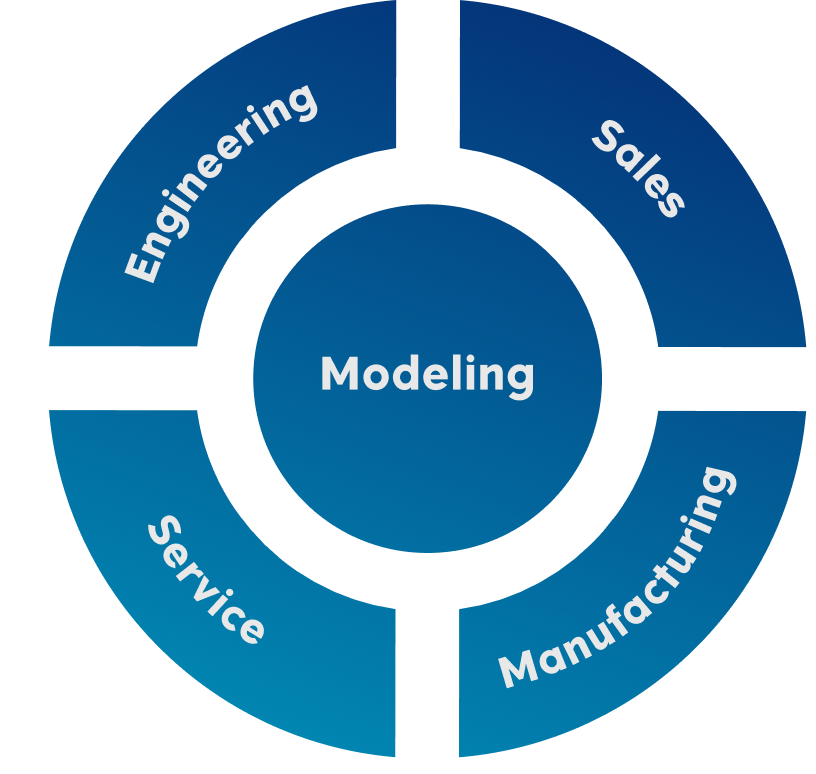

CLM is a comprehensive approach to managing the entire lifecycle of product configurations. CLM is about ensuring accuracy, consistency, and control over how products are defined and delivered, especially when those products are highly configurable or complex.

By acting as a shared source of truth for product configuration data, CLM provides a structured framework for managing the complexities of configurable products throughout their entire lifecycle, enabling the automation of manual, document-driven processes. This helps companies reduce errors, accelerate time-to-market, and enhance customer satisfaction by ensuring that products are configured and delivered correctly.

Could Your Organization Benefit from a CLM Approach

Beyond its core benefits, CLM can significantly mitigate the impact of a retiring workforce, particularly in industries dealing with complex, configurable products, by:

![]() Capturing and Preserving Knowledge:

Capturing and Preserving Knowledge:

-

- Retiring employees often possess extensive knowledge about product configurations, rules, and variations. Using a CLM approach to capture and codify this knowledge into structured data ensures it’s not lost when they leave.

- In addition, these configuration rules, constraints, and best practices can be documented and stored within the CLM system, creating a valuable knowledge repository.

![]() Improving Training and Onboarding:

Improving Training and Onboarding:

-

- With its shared source of truth easily accessible, CLM makes it easier to train and onboard new employees quickly.

![]() Enhancing Collaboration:

Enhancing Collaboration:

-

- CLM facilitates collaboration between different teams and departments, ensuring that everyone has access to the same accurate and up-to-date configuration information. This reduces the risk of miscommunication and errors, especially during periods of workforce transition.

As a knowledge repository, CLM ensures that critical configuration expertise is retained and accessible, even with employee retirement and attrition. This helps manufacturers:

- Close the skills gap.

- Maintain consistent and efficient operations during workforce transitions.

- Minimize disruptions.

- Ensure production continuity.

Struggling with the skills gap in manufacturing?

Daniel Joseph Barry is VP of Product Marketing at Configit. Dan Joe has more than 30 years of experience in engineering, sales, marketing, product management and strategy roles within IT and telecom companies.