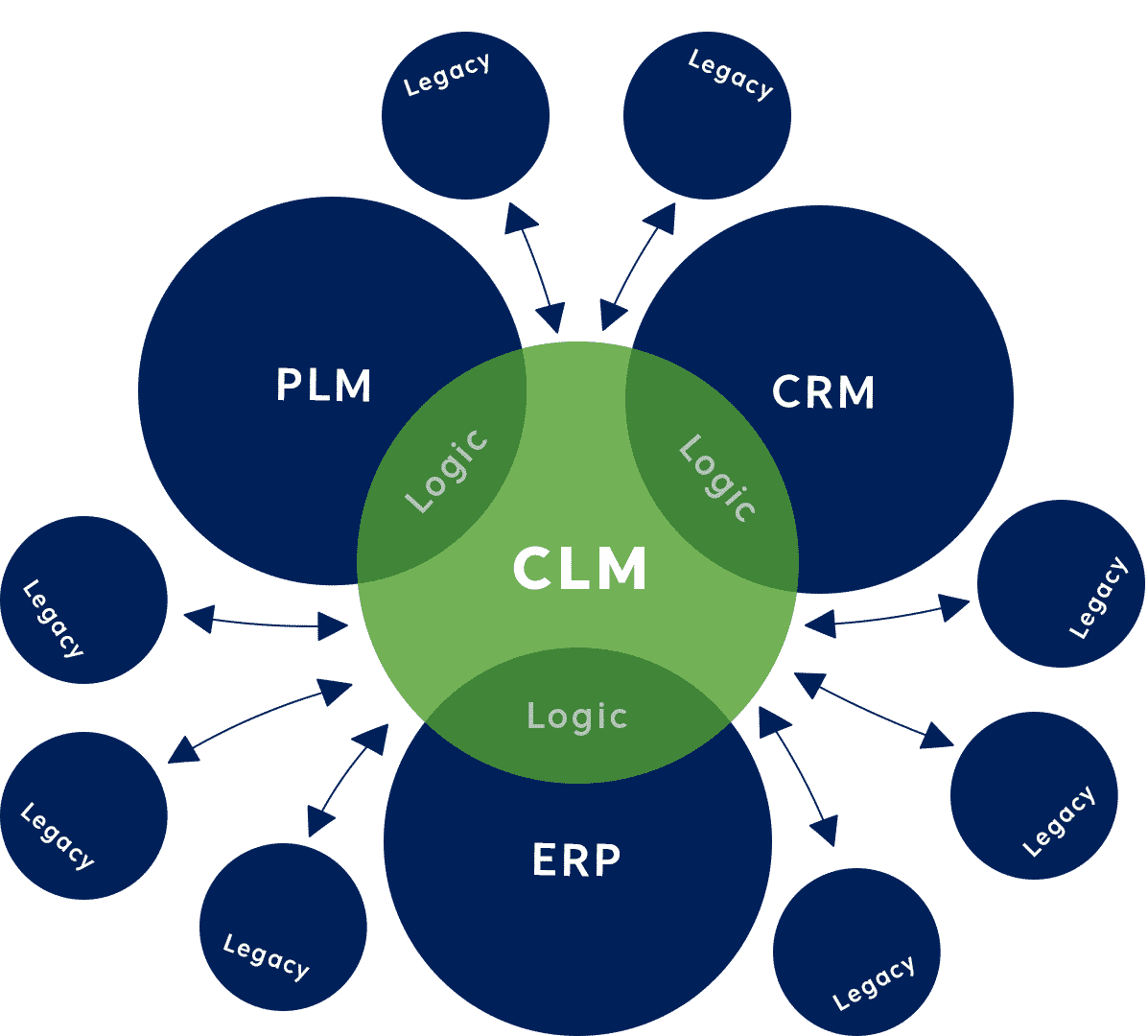

Capture More Value with Less Disruption Using Configuration Lifecycle Management (CLM)

Connecting data across functions not only eliminates errors due to siloed information, it also accelerates the development, manufacturing and sales of products and services.

Having a shared source of configuration truth provides greater operational efficiency across the organization, providing both internal value of cost savings and increased sales, and external value of enhanced customer experience and increased brand loyalty.

The result is a smooth, error-free process that creates a more competitive business with higher customer satisfaction, long-term stability and increased profitability.