Configuration Management vs Configuration Lifecycle Management: What’s the Real Difference?

In today’s digital manufacturing world, configuration control is more important than ever. Complex products, global supply chains, and increasing demand for customization make it essential for companies to manage their configurations accurately and efficiently.

Two key terms dominate this space: Configuration Management (CM) and Configuration Lifecycle Management (CLM). While they sound similar, they serve slightly different purposes.

Recognizing that CM and CLM are complementary, not competing, approaches enables global manufacturers to manage complexity, improve quality, and accelerate digital transformation.

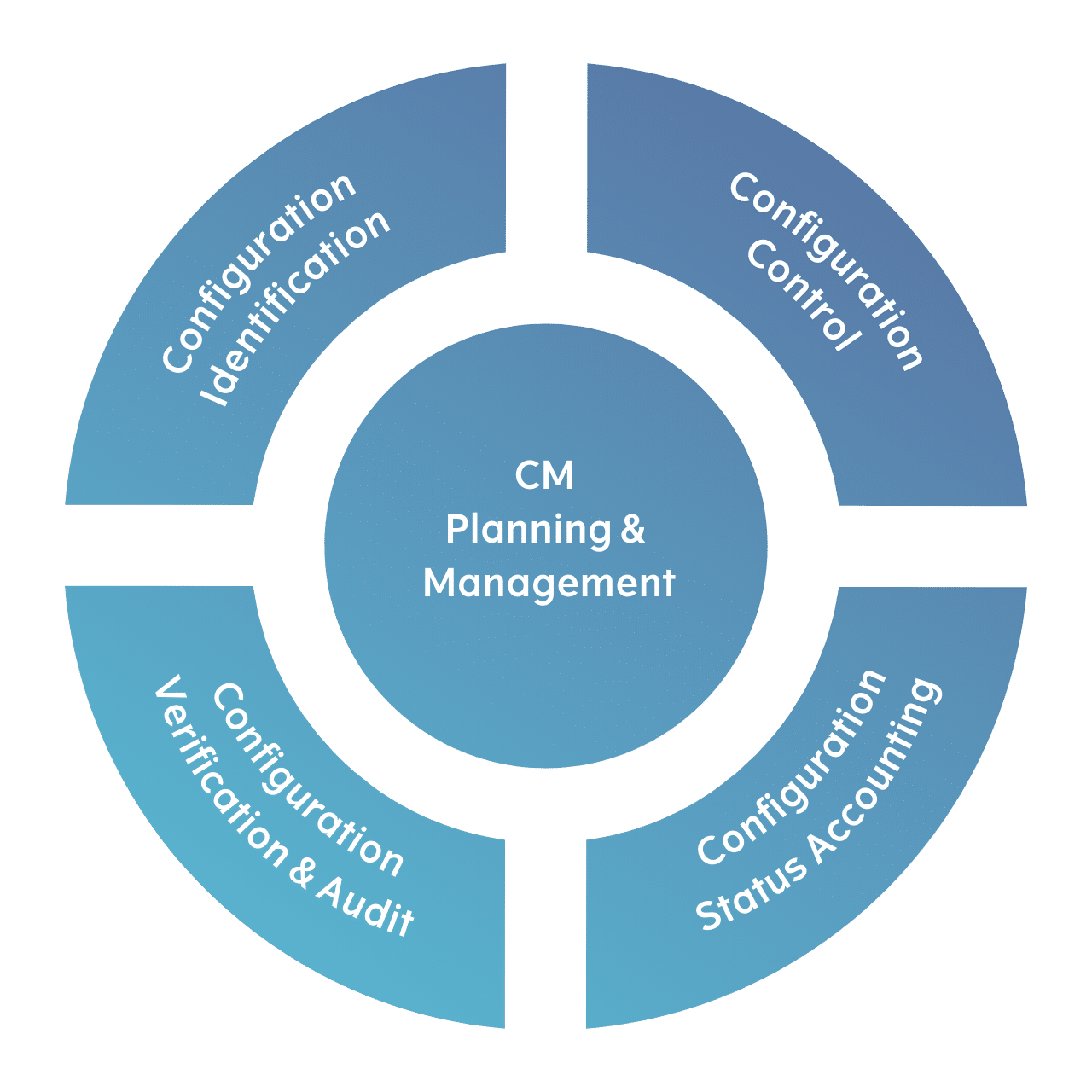

What Is Configuration Management (CM)?

Configuration Management has many definitions. For example, NIST defines CM as a collection of activities focused on establishing and maintaining the integrity of information technology products and systems, through control of processes for initializing, changing, and monitoring the configurations of those products and systems throughout the system development life cycle.

Another definition, from ISO 10007:2017, states that CM is a discipline applying technical and administrative direction and surveillance to: identify and document the functional and physical characteristics of a product, control changes to those characteristics, and record and report change processing and implementation status.

There is yet another definition regarding IT and, more specifically, cybersecurity, that defines it as the process of establishing and maintaining the integrity of manufacturing system hardware and software components by controlling processes for initializing, changing, monitoring, and auditing configurations throughout the system development life cycle.

As you can see, Configuration Management in this context is more about quality control, change management and traceability. It’s about baselining all assets associated with the development and maintenance of a product and recording any changes made over the lifetime of the product.

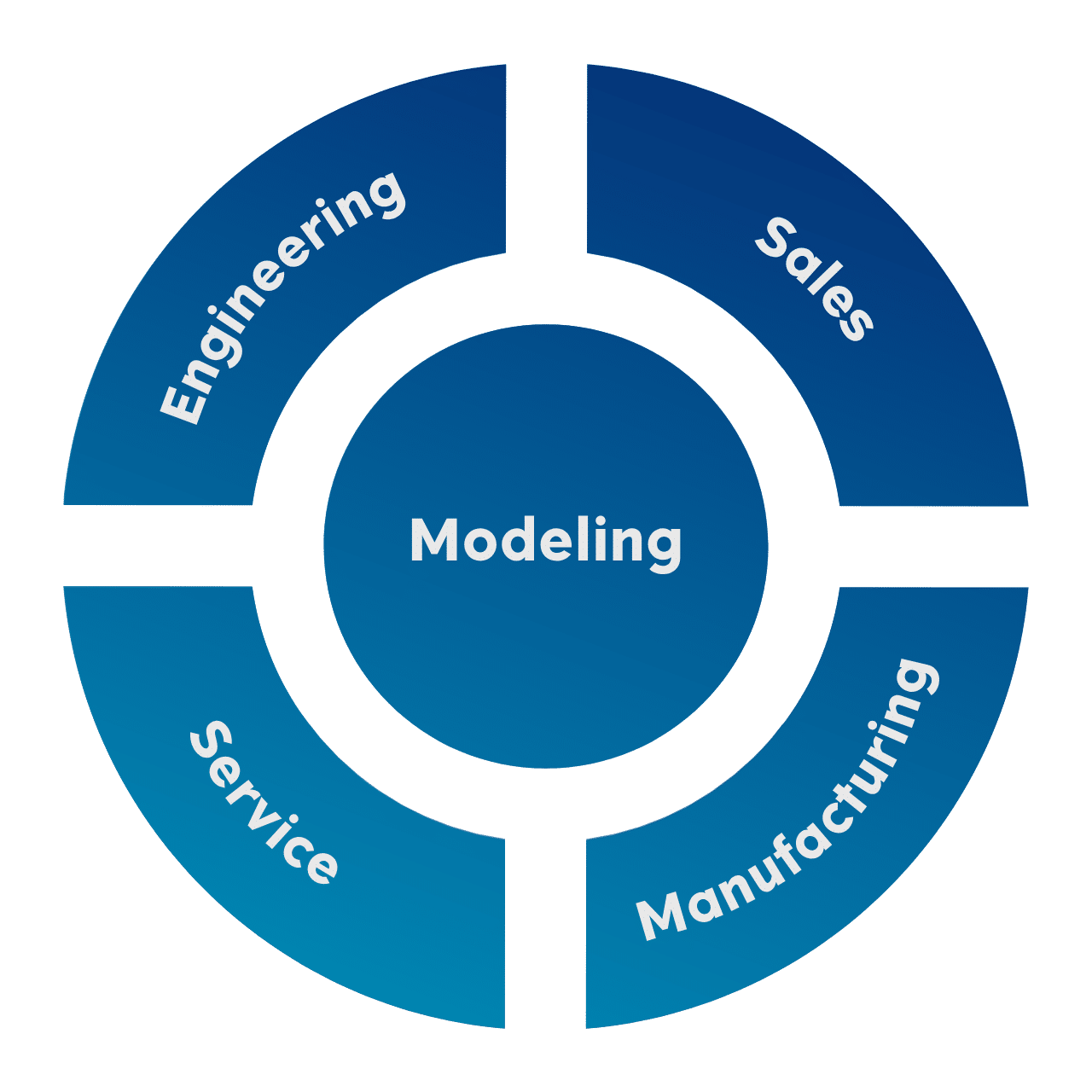

What Is Configuration Lifecycle Management (CLM)?

Configuration Lifecycle Management (CLM) is about managing available product variants (i.e. Which configurable options are available), ensuring that they are deliverable and then managing the specific product configurations ordered by customers throughout the lifecycle of the product.

CLM is a data-driven, integrated approach that connects Product Lifecycle Management (PLM), Enterprise Resource Planning (ERP), Configure Price Quote (CPQ), and other enterprise systems around product configuration data, creating a shared source of truth.

Key Benefits of CLM

- Real-time product configuration visibility across all functions

- Validation and alignment of product configuration data in multiple systems and formats

- End-to-end traceability from concept to customer delivery to continuous maintenance

- Digital continuity that connects design, production, and service data

- Support for mass customization and product variability

CLM focuses on managing the product configurations offered to customers as well as the product configurations made by end-users throughout the product lifecycle. In that regard, it contributes to overall configuration management for traceability, insight, and quality control.

Learn How Configit’s Configuration Lifecycle Management (CLM) Complements PTC’s PLM by Breaking Down Silos Between Engineering and Sales

Configuration Management (CM) and Configuration Lifecycle Management (CLM) are not competing approaches. They are complementary disciplines that work best together. Each addresses a different aspect of managing complexity across the product lifecycle, and together they form a more complete foundation for quality, governance, and collaboration.

The Role of Configuration Management (CM)

Configuration Management governs both digital and physical assets throughout the product lifecycle. It provides the control, traceability, and compliance structure needed to ensure that every product version is properly documented, approved, and verified.

CM is essential for quality control and governance, ensuring that organizations maintain consistency, meet regulatory standards, and have full visibility into every configuration change.

The Role of Configuration Lifecycle Management (CLM)

Configuration Lifecycle Management solves a different but related challenge. While CM focuses on governance and control, CLM ensures that information about product variants is accessible, connected, and actionable across departments and systems.

CLM provides a centralized, validated source of product configuration data that links engineering, manufacturing, sales and service. This creates transparency across the organization and enables faster, more informed decision-making. In this way, CLM contributes valuable insights and real-time data to the overall CM initiative, strengthening quality control and lifecycle visibility.

As products become smarter and more connected, traditional CM alone cannot manage the complexity of millions of product variants. Global manufacturers need integrated systems that support real-time updates, configuration traceability, and collaboration across teams and partners.

Configuration Lifecycle Management (CLM) provides that capability by creating a shared source of truth for all product configuration data.

Key CLM Advantages for Global Enterprises

- Faster time-to-market with synchronized data

- Reduced rework and production errors

- Better collaboration between design, manufacturing, and sales

- Greater customer satisfaction through accurate product configurations

- Full lifecycle traceability for compliance and quality assurance

Ready to Move Beyond Traditional Configuration Management?

Configuration Management is essential to ensure that a given product’s functional and physical characteristics are consistently identified, documented, controlled, and kept aligned throughout its lifecycle. It establishes the foundation for product consistency.

Configuration Lifecycle Management takes that foundation further by managing all possible product variants in a single digital thread. It transforms configuration data from static records into a strategic business asset that supports innovation, customization, and global collaboration.

For organizations navigating the challenges of digital transformation, CLM is no longer optional; it is the new approach to managing product configurations across the enterprise.

Henrik Hulgaard is the Vice President, Product Management and co-founder of Configit, a global Configuration Lifecycle Management (CLM) solution provider and a supplier of business-critical software for configuring complex products. He holds a PhD in computer science from the University of Washington and is an associate professor of computer science. He has published more than 25 articles internationally.