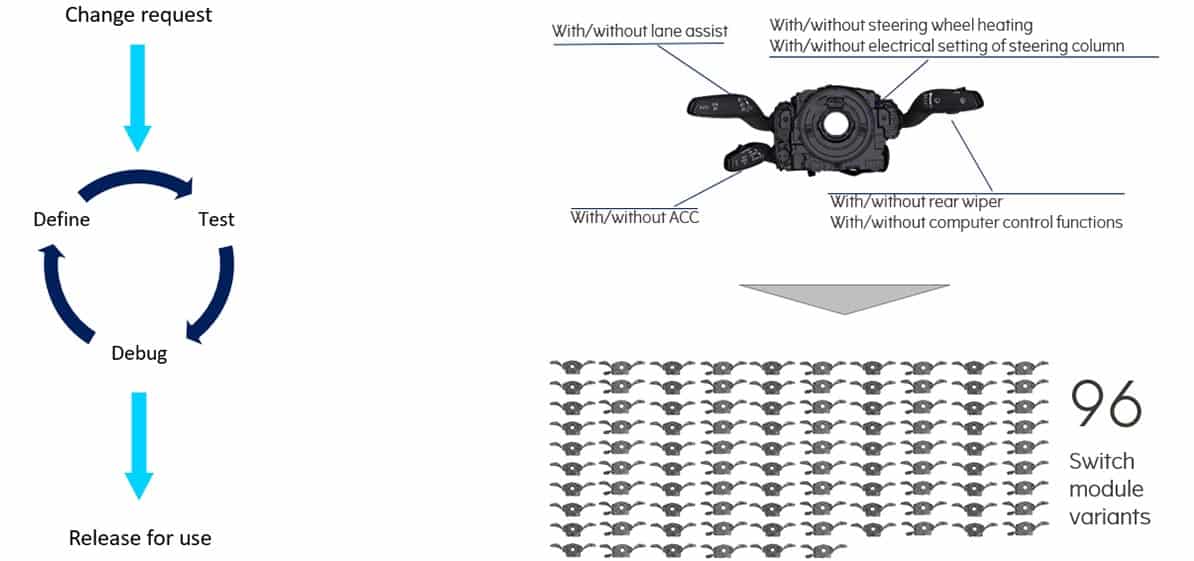

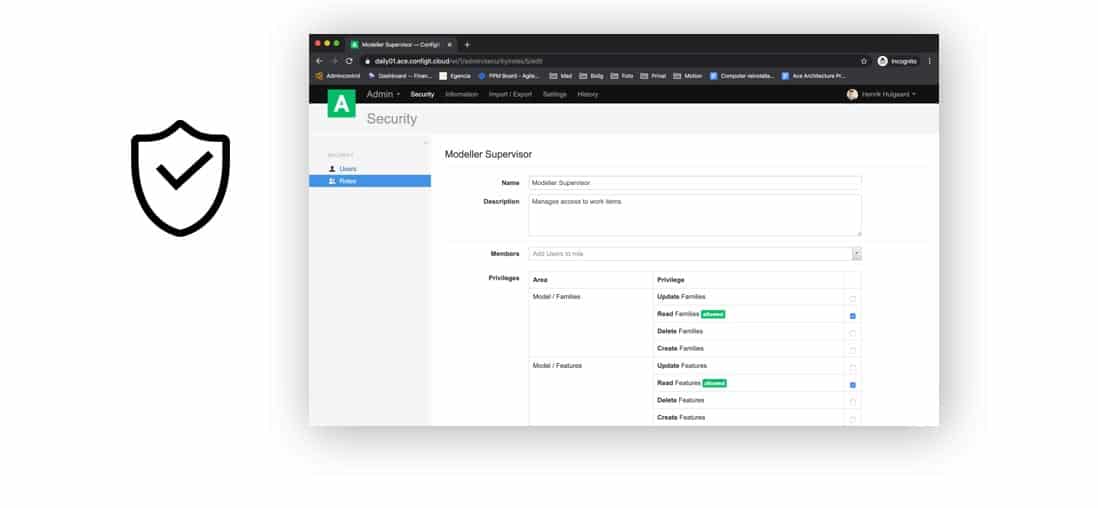

At Configit, we believe being able to quickly try things out, iteratively collaborate, analyze ‘what if’ scenarios, are keys to having a strong culture of innovation. With an outside-in perspective that is more top down from sales, rather than bottom up from engineering, can accelerate product development and new product introduction.

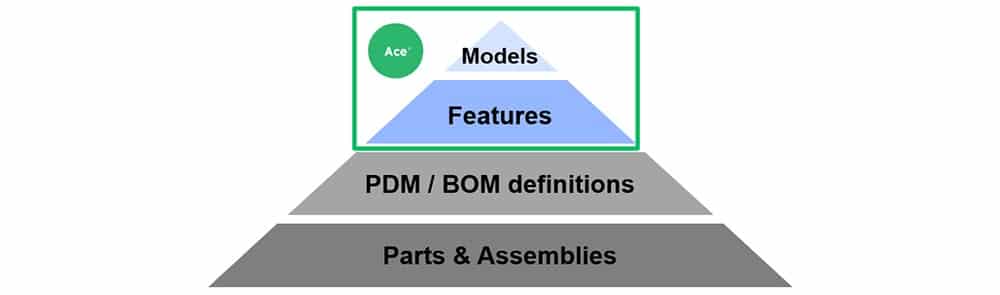

Products Models are Key

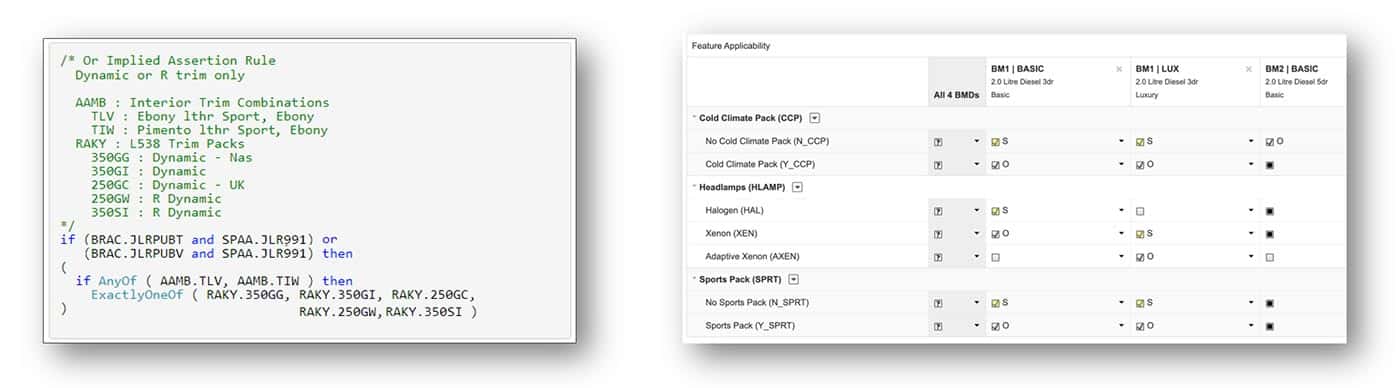

A key element of End-to-End Configuration is getting the functional areas of your organization to share the features of the product. These features become the key language in how you talk about the variability of a product; not so much the parts themselves and the individual part numbers, but more so the capabilities of the product. And in the center of this you have the modeling aspect, and this is what we will explain in a little more detail.