Validate, Analyze and Align Your PLM and ERP Product Configuration Models

Key Benefits of Aligning Engineering and Sales Intent by Validating PLM and ERP Data and Rules with Configit Ace®

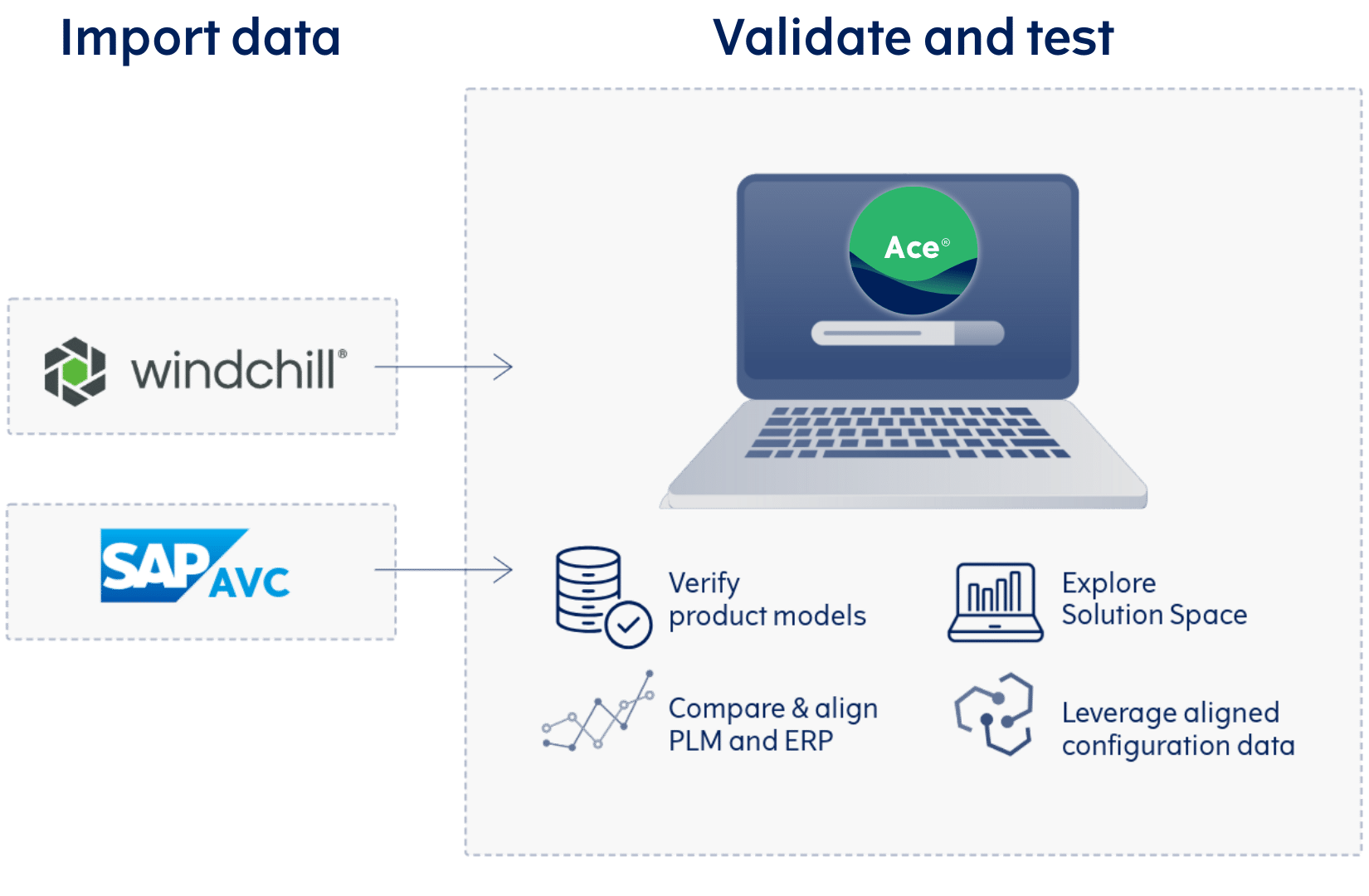

Validate product models

Configit Ace® identifies blocked values and provides guidance on how to resolve gaps, conflicts, and misalignments across models.

Explore precomputed Solution Space

Visualizations provide new insights and better understanding of what is being offered.

Compare and align PLM and ERP

Identify inconsistencies between systems to eliminate errors, speed up product releases, and improve cross-functional collaboration.

Leverage aligned configuration data

Enable accurate, real-time consumption of validated configuration data across manufacturing, sales, and service platforms.

How to Integrate, Validate and Align PLM and ERP Configuration Data

You simply select your product configuration models and data to validate, we ensure the process is seamless and immediate.

Results:

Demo

Leverage the Power of Configit Virtual Tabulation® and Solution Space Analysis to:

Used by Global Leaders in Renewable Energy to Streamline Complexity and Accelerate Delivery

Customer Case: How Vestas Resolved Configuration Chaos with a Unified Platform Approach

With their product data managed in multiple systems, Vestas was relying on a few expert people, manual processes and workarounds resulting in slower time to market.

Vestas centralized their product configuration data from PTC Windchill and regional market rules from SAP into a shared source of truth using Configit Ace®.

Greater efficiency enabled Vestas to create sales configurations in five minutes, compared with the 60 minutes it used to take. They can now support many more product variations with the same resources, validate 100% of the BoM, and introduce new products faster to market.

Configit Ace® is Trusted by the World’s Largest Manufacturing Companies

The key benefits to us were efficiency, and based on the Configit solution were able to make a sales configuration in just 5 minutes, instead of 60.

Henry Farrell,

Head of Digital Commercial – Digital Solutions Organization, Vestas

Seamless, Secure, Enterprise Ready

Open REST APIs for Seamless Integration

✔ Easily integrate with PLM, ERP, MES, CPQ, and CRM

✔ Enrich or replace – Author and maintain data in existing systems or in Configit Ace®

Enterprise-Grade Security

✔ SOC2, ISO 27001 and ISO 27017 ensure information and cloud security and confidentiality

✔ Traceability from design, to sales, to manufacturing and service with Configit Ace®

FAQs

✔ “Which PLM and ERP are supported?” → Built on PTC Windchill and SAP, with flexibility to integrate other systems via APIs

✔ “How long does validation and analysis tasks take?” → All interaction are instantaneous

✔ “Can I analyze the entire Solution Space?” → With up to 10²⁰⁰ configurations, a targeted feature analysis is recommended