How products are designed and brought to market can also be very different from one manufacturer to the next. For the sake of simplicity, we can consider three different models:

- Model 1 – Customers specify requirements, which are first delivered as a prototype and, upon approval, used as a basis for delivering according to detailed customer specifications

- Model 2 – Marketing specifies requirements based on customer and market trend input, which is used to create detailed product specifications for products that can be sold to multiple customers with specific product variants and potential customization

- Model 3 – Engineering specifies the product with multiple product variants and customization options that are released to production and then to sales

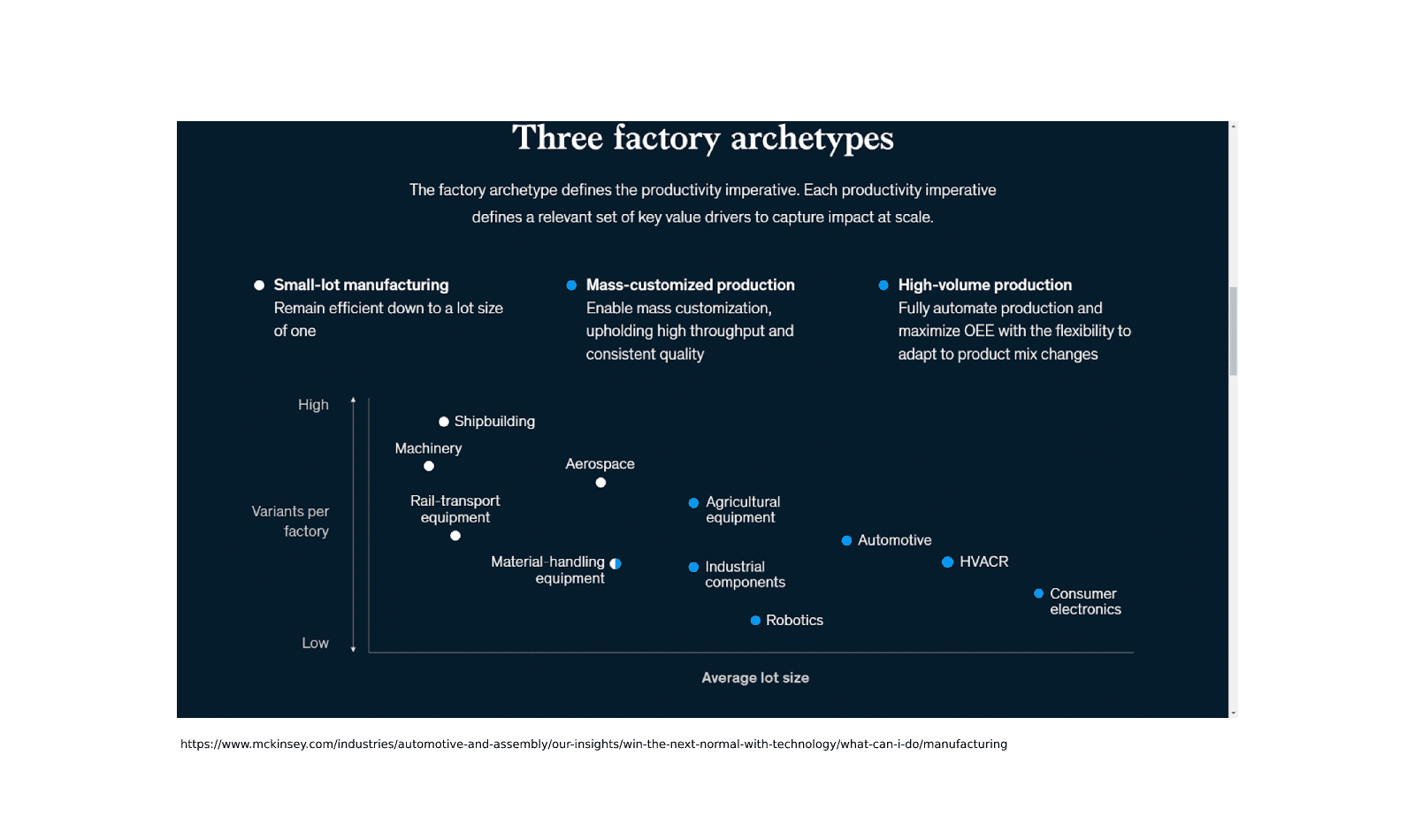

Model 1 faces the complexity challenge of managing customized products for each customer where the hope is that generic components can be re-used. This is typical of small-lot manufacturing.

Models 2 and 3 face the complexity challenge of accommodating and managing all potential product variants and customizations and ensuring that no configuration option has been forgotten.

Only profitable options survive and non-profitable options are discontinued. This is typical of mass-customized and high-volume production.

Models 1 and 2 are “outside-in” driven where input on product ideas and improvements are received from customers and/or the market. Collaboration between all functions is essential in ensuring that the right product options are being designed and delivered.

Model 3 is “inside-out” driven and should require close collaboration to ensure all the right options are being considered. However, there are still many manufacturers using a sequential engineering approach with “over-the-wall” hand-offs to manufacturing, marketing and sales. This approach will increasingly be challenged as product lifecycles decrease and customer demands and associated product complexity increase.

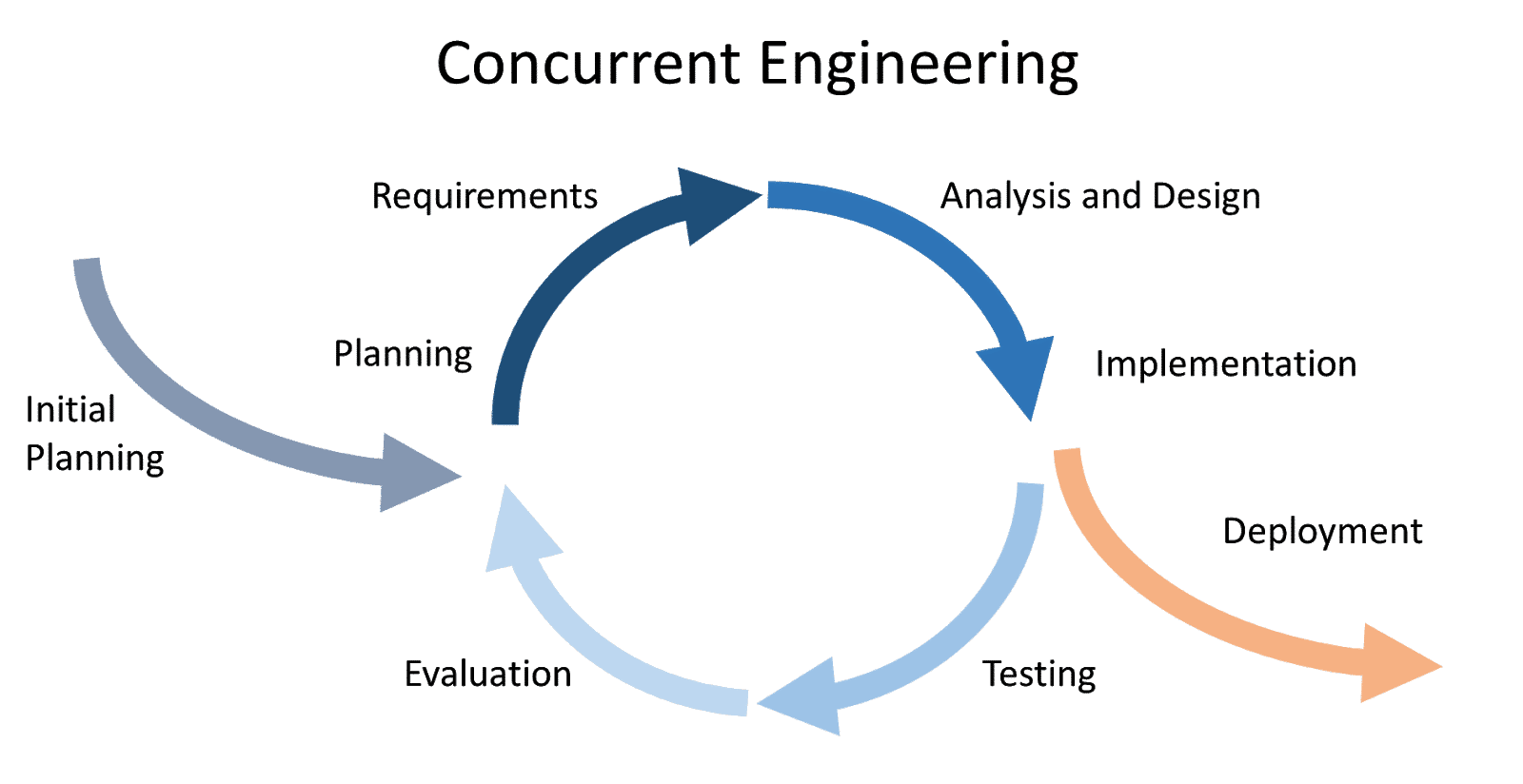

To address shorter product lifecycles and increased complexity, more agile approaches to engineering are required, typified by Concurrent Engineering (CE) and similar approaches.

Concurrent Engineering, or Simultaneous Engineering, is an integrated product development approach where all the lifecycle aspects of a product are considered simultaneously rather than sequentially. Iterative prototyping and modeling considering the entire lifecycle of the product uncovers potential challenges early and enables re-design that is faster and lower cost than discovering issues once the design and product have been released.