In 2021, the term ‘supply chain’ became part of the vernacular. No matter what you were looking for, from a loaf of bread to an automotive component, supply chain woes seemed to touch everyone’s life.

In the complex world of global manufacturing, supply chain issues are long known to throw a wrench in the delivery of products.

One of our customers felt this acutely in 2011 following the tsunami in Japan that destroyed the factory that was manufacturing a specific paint color for their vehicles. Whether it’s scarcity of raw materials, labor shortages, or natural disasters, weaknesses in supply chains can’t be fully avoided, but can be mitigated.

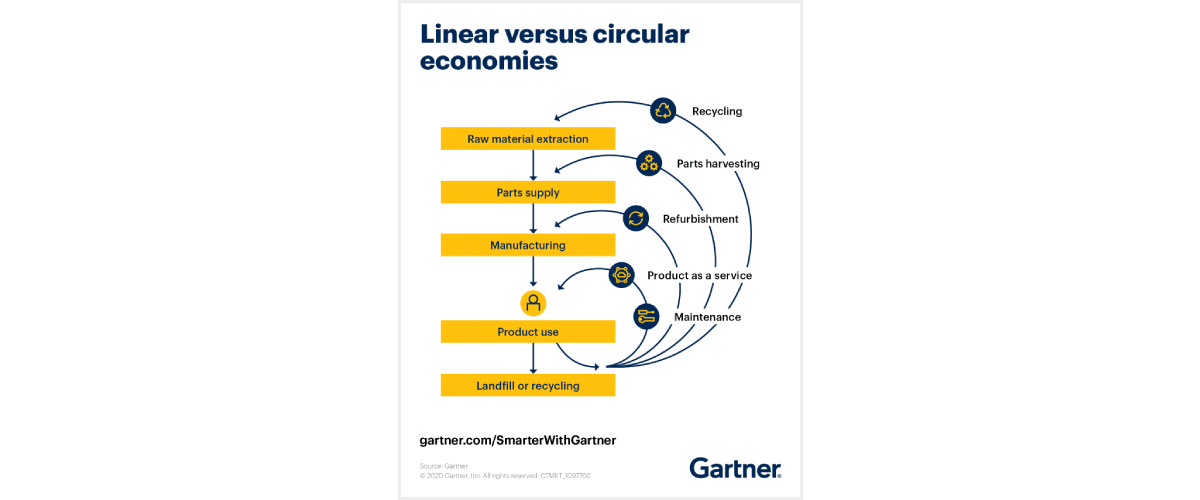

A recent Gartner article discussed the role a circular economy can play not only in maintaining a healthy, resilient supply chain, but in supporting sustainability goals and initiatives. I’ve written a lot lately about sustainability in manufacturing, and can’t help but see similarities between sustainability and the circular economy model.