From Engineer-to-Order to Configure-to-Order: The Next Era of Manufacturing

For decades, manufacturers have relied on Make-to-Order/Engineer-to-Order (MTO/ETO) to meet customer demands. Today, industry leaders are moving to Configure-to-Order (CTO) and hybrid CTO+ models to cut complexity, boost speed, and unlock scalable growth.

In today’s hyper-competitive manufacturing landscape, the ability to deliver customized products quickly and profitably can make or break a business. While Engineer-to-Order (ETO) and Make-to-Order (MTO) have long been the standard for complex product manufacturers, a growing number of industry leaders are discovering the transformative benefits of shifting to a more Configure-to-Order (CTO) approach.

Companies like ABB, Vestas, and Viessmann have already made this transition, achieving remarkable results.

- 76% ROI improvements

- 92% reduction in configuration errors

- dramatic acceleration in time-to-market

But what exactly drives these impressive outcomes, and how can your organization make this strategic shift successfully?

Engineer-to-Order: The Traditional Approach

In an ETO model, each customer order triggers a unique engineering process. Engineers design products from scratch or heavily modify existing designs to meet specific customer requirements. While this approach offers maximum customization, it comes with significant challenges:

- Extended lead times as engineers design and validate each configuration

- High engineering costs for every project

- Increased risk of errors due to manual processes

- Limited scalability as growth requires proportional engineering resources

- Inconsistent pricing and delivery timelines

Configure-to-Order: The Modern Solution

CTO represents a paradigm shift where products are designed with built-in configurability. Instead of engineering each order from scratch, sales teams and customers select from pre-engineered options and modules that automatically combine into valid, manufacturable configurations.

The good news is that this doesn’t mean sacrificing customization. It means intelligent customization within a framework that ensures every configuration is technically feasible, profitable, and can be delivered quickly.

In practice, most global manufacturers end up with a hybrid of ETO and CTO that enables them to consolidate a portion of their product lines into easily configurable modules, while still maintaining the ability to offer custom, bespoke ETO solutions. The result is significant cost savings across the value chain.

Is Your ETO Process Holding Back Your Ability to Scale?

Dramatically Reduced Time-to-Market

The Challenge: In ETO, engineering cycles can extend project timelines by weeks or months. Every custom specification requires design work, validation, and approval cycles.

The CTO Solution: Pre-engineered configurability means quotes can be generated in minutes rather than weeks. Sidel, a Configit customer, reduced their quoting time from 15 minutes to under 10 seconds – a 90x improvement in speed.

Significant Cost Reduction

Engineering Efficiency: CTO eliminates repetitive engineering work by front-loading the design effort. Instead of re-engineering similar solutions repeatedly, engineers focus on expanding configurability and developing new product modules.

Operational Savings: Standardized configurations reduce manufacturing complexity, inventory requirements, and quality issues. Companies typically see 20-40% reduction in engineering costs when transitioning to CTO.

Resource Optimization: Engineering talent can focus on innovation and new product development rather than repetitive customization work.

Zero Configuration Errors

The ETO Problem: Manual engineering processes are inherently error prone. A single misconfiguration can result in products that can’t be manufactured, don’t meet specifications, or fail in the field – leading to costly rework and damaged customer relationships.

CTO’s Built-in Validation: With proper configuration technology, every possible combination is pre-validated. Invalid configurations simply cannot be created, eliminating the risk of selling unbuildable products.

Real-World Impact: Companies using advanced configuration systems like Virtual Tabulation® report zero configuration errors in their sales processes.

Enhanced Scalability

ETO Scaling Challenges: Growing an ETO business traditionally requires hiring more engineers proportionally. This creates escalating costs and management complexity.

CTO Scaling Advantages: Once configuration systems are established, revenue can grow without proportional increases in engineering resources. Sales teams can handle more complex products confidently, and customers can even self-serve through online configurators.

Improved Customer Experience

Faster Quotes: Customers receive accurate pricing and delivery information immediately rather than waiting for engineering estimates.

Self-Service Options: Online configurators enable customers to explore options independently, understanding trade-offs and pricing in real-time.

Consistency: Every customer interaction delivers the same high-quality, accurate information regardless of who handles the inquiry.

Driving Success in the Shift from ETO to CTO - Deloitte's Perspective

Successful CTO transformation requires more than just good intentions – it demands robust technology infrastructure. This is where a Configuration Lifecycle Management (CLM) approach becomes critical.

Virtual Tabulation®: The Game-Changing Technology

Traditional configuration engines struggle with complex products, often forcing companies to oversimplify their offerings. Virtual Tabulation® takes a different approach by pre-computing every possible valid configuration and compressing this information into compact, portable files.

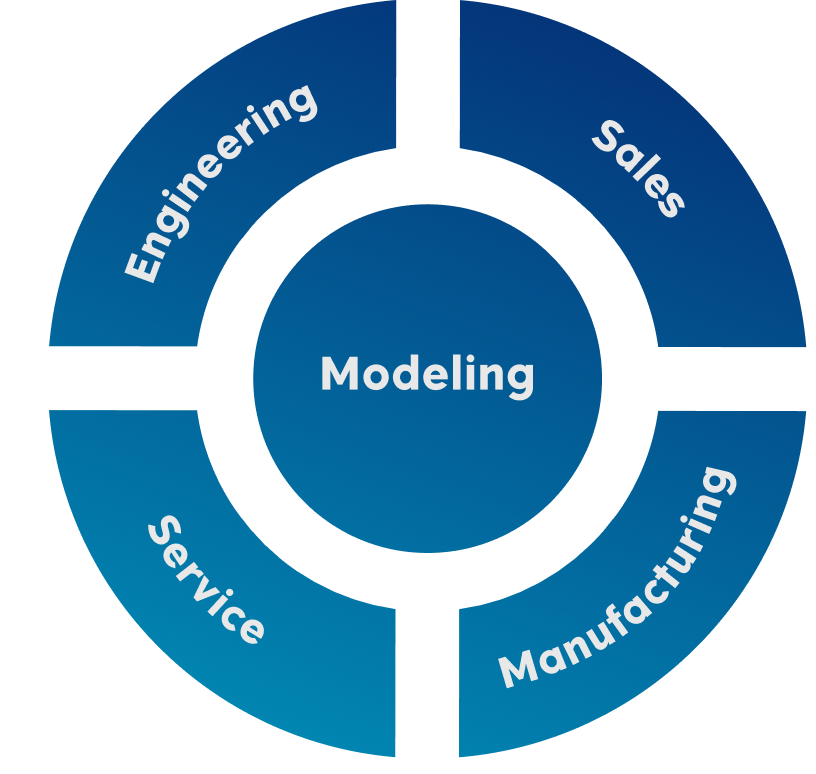

By combining product configuration data from across the enterprise – from Sales, Engineering, Manufacturing and Service – into one shared source of truth, organizations have the transparency and clarity needed to identify those product combinations that are most and least ordered, creating the building blocks of a Configure-to-Order transition.

Key Advantages:

- Instant validation of any configuration

- Perfect guidance for sales teams and customers

- Zero errors because invalid combinations are impossible

- Unlimited complexity handling millions of combinations

End-to-End Integration

Using a CLM approach connects the entire organization:

- Engineering defines configurability and rules

- Sales creates quotes with confidence

- Manufacturing receives validated specifications

- Service understands installed configurations

This shared source of truth eliminates the disconnects that often plague traditional ETO processes.

The manufacturing industry is at an inflection point. Customer expectations for speed and customization continue to rise while cost pressures intensify. Companies that cling to traditional ETO approaches risk being left behind by more agile competitors.

The question isn’t whether to evolve – it’s how quickly you can transform.

Early adopters of CTO are already capturing market share by delivering what seemed impossible: mass customization at the speed and cost of mass production.

Transitioning from exclusively ETO to CTO/CTO+ hybrids represents one of the most significant competitive advantages available to complex product manufacturers today. The companies making this shift are seeing dramatic improvements in speed, accuracy, cost, and customer satisfaction.

Experience How Configit Simplifies the Shift from ETO to CTO

Daniel Joseph Barry is VP of Product Marketing at Configit. Dan Joe has more than 30 years of experience in engineering, sales, marketing, product management and strategy roles within IT and telecom companies.