Future Trends in

Sustainability Regulations for Manufacturers

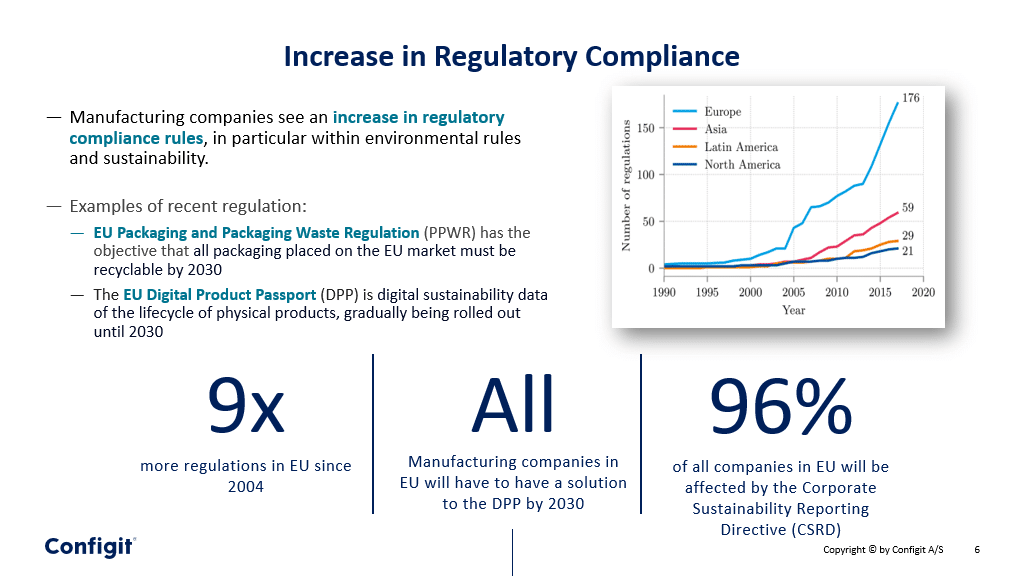

Over the past 50 years, environmental regulations have undergone a dramatic transformation, shifting from a reactive approach to a more proactive one.

From the Clean Air Act and establishment of the Environmental Protection Agency in 1970, through to the Paris Agreement in 2015, the evolution of environmental regulations reflects a growing awareness of the interconnectedness of our planet and the need for responsible stewardship.

As environmental challenges continue to evolve, we can expect regulations to adapt and become even more comprehensive in the years to come.

While the impact of upcoming regulations for manufacturers varies depending on the specific industry, company size, and location, it can be a complex challenge for manufacturers to navigate.

The good news is that today’s software can help companies create sustainable manufacturing practices by effectively managing the data needed for both reporting mandates, as well as upcoming product modifications required under future regulations.

To meet regulations or cater to growing consumer demand for sustainable products, manufacturers may need to redesign products using recyclable materials, lower energy consumption components, or with longer lifespans. For those manufacturers using Configit Ace®, a key feature that is available to them is the effectivity date function, which can help organizations in preparing for upcoming regulatory changes in manufacturing.

Effectivity dates clearly mark when a specific version of a product component, design, or document becomes active or is retired, providing a clear historical record of changes and preventing confusion when working with multiple versions. With Configit Ace®, manufacturers can facilitate rollouts and phase-outs of new product features or revisions well in advance. Teams can plan for the transition by setting the effectivity date for the new version and ensuring all stakeholders are aware of the change.

Because certain industries have strict regulations regarding product safety and functionality, for example automotive or industrial machinery, effectivity dates help ensure products comply with the correct regulations at the time of manufacture and sale. By tracking effectivity dates, companies can demonstrate compliance with sustainable manufacturing practices and simplify audits.

This reduces the risk of errors caused by using outdated information and ensures everyone is working on the same version of a product. Effectivity dates can help track the use of specific components in different product versions. This allows for better inventory planning and avoids situations where older versions of components become obsolete and unusable.

For example, companies needing to sunset toxic materials such as freon in air conditioners, eliminating gas-powered internal-combustion vehicles by a certain date, or reducing the amount of plastic in products would all benefit from an effectivity date feature in their enterprise software system.

Effectively Manage Configuration Changes with the Least Amount of Effort

While sustainability regulations for manufacturers can pose challenges initially, they ultimately encourage manufacturing practices that promote resource efficiency, waste reduction, and a more sustainable future. This can have long-term benefits for companies and the environment, promoting a more responsible and environmentally friendly approach to production.

About the Author

Daniel Joseph Barry is VP of Product Marketing at Configit. Dan Joe has more than 30 years of experience in engineering, sales, marketing, product management and strategy roles within IT and telecom companies.