- Discrete Manufacturing, Transportation and Logistics, and Utilities will lead all industries in IoT spending by 2020, averaging $40B each.

- Bain predicts B2B IoT segments will generate more than $300B annually by 2020, including approximately $85B in the industrial sector alone.

- The Internet of Things (IoT) market is projected to reach $267B by 2020 according to the Boston Consulting Group.

- PwC predicts Industry 4.0 will drive $493B in revenue gains and $421B in cost reductions globally by 2020.

- Manufacturers predict 47% of all their products will be smart, connected and capable of generating product-as-a-service revenue by 2020.

Why Every Manufacturer Needs Digital Transformation To Grow

The era of customer-driven, digital manufacturing is here.

Manufacturing is the world’s most data-prolific industry and a quick analysis of the myriad of data produced just this year validate five key factors fueling digital transformation industry-wide. The five factors driving digital transformation include the following: becoming collaborators in creation with customers; defining and delivering smart, intelligent products including those that generate products-as-a-service revenue; digitally transforming quality into a continuous improvement cycle; introducing Internet of Things (IoT) and successfully integrating diverse technologies to support business goals; and defining compelling digital transformation goals to optimize existing processes while launching new business models.

Start By Digitally Transforming Customer Experiences

Customers’ trust, loyalty and lifetime value is the fuel that makes all digital transformations succeed. In manufacturing, it is the rocket fuel that propels digitally-driven process optimization to succeed. And it’s the excitement in a new digital business model that makes it resonate with existing and new customers and succeed.

And it’s winning and reinforcing customers’ trust that is the galvanizing force that makes the heart of digital transformation strong. When manufacturers work to earn trust by digitally optimizing and improving every detail of customer experiences, digital transformation projects deliver more than expected. And new business models flourish when they seek to overwhelm customers with value.

Taking a customer-centric view of digital transformation leads to defining goals in these two areas first:

- Prioritize and optimize existing customer-facing processes first. Digital transformation goals in this area center on improving existing distribution, selling and service channels to deliver higher quality customer buying experiences. Manufacturers are digitally enabling all channels today to achieve greater personalization at scale. Digitally transforming customer-facing processes relies heavily on real-time integration between all virtual and physical selling locations. Manufacturers who excel in this area of digitally transforming their businesses can achieve premium pricing while improving virtual and physical channel sales, leading to faster revenue growth.

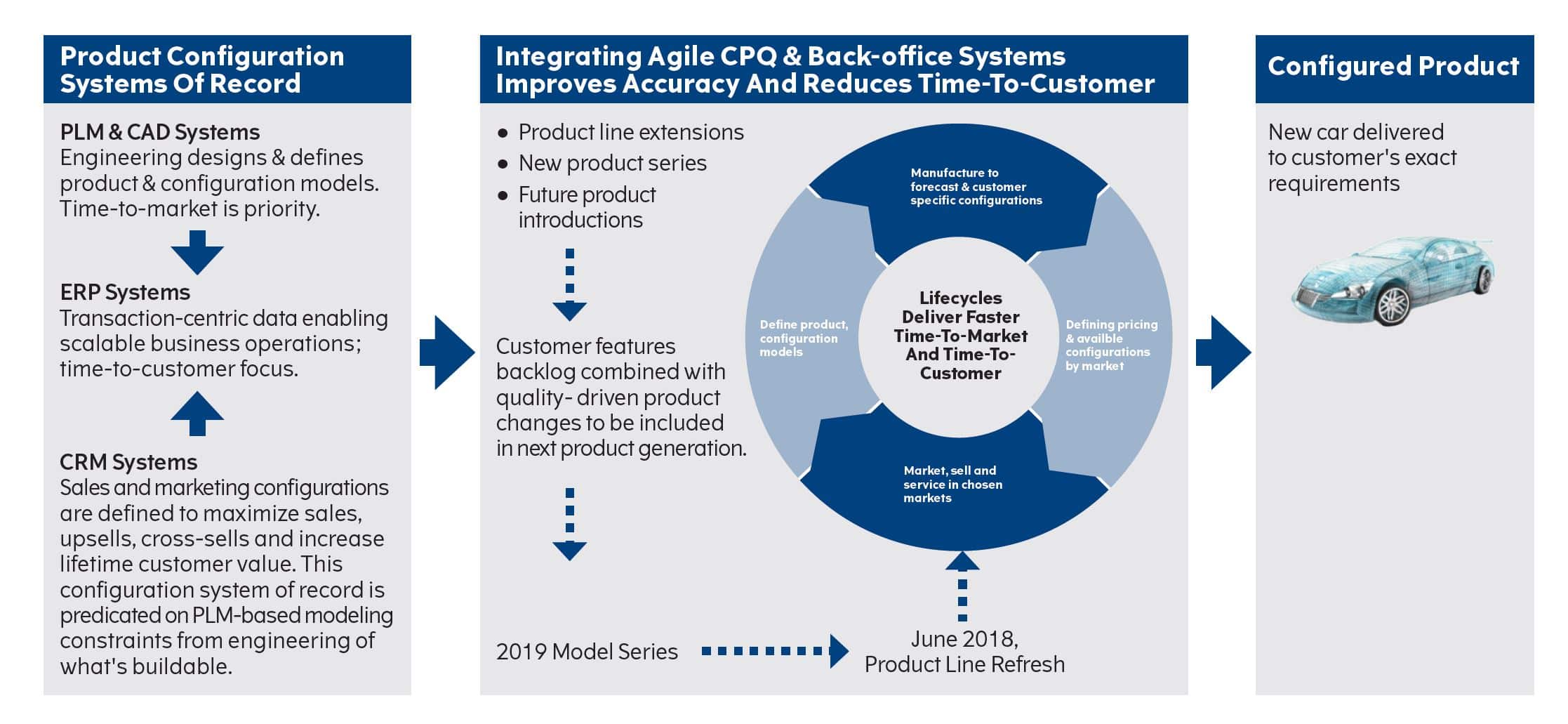

- Digitally transform legacy processes to support new business models. No industry has a greater opportunity to become collaborators in creation with their customers than manufacturing, make this one of the main success factors of digital transformation. Manufacturers need to accept the challenges of being stronger collaborators with customers. To do this, the three core systems that form the heart of any manufacturer need to be synchronized to a common goal of delivering excellent quality products on time, perfectly matched to customers’ requirements. Digitally transforming CRM, PLM and ERP systems, so they are orchestrated into a unified strategy that supports products over their lifecycles is the best place to start.

Start Digitally Enabling Customer-Facing Processes First

By digitally transforming customer-facing processes first, manufacturers are achieving the ability to deliver personalized products and services at scale. Digitally transforming distribution, sales and service channels is where most successful efforts start. That’s followed by redefining each customer process with the goal of improving their experiences.

Exceptional manufacturers know how their customers perceive time and realize it’s very different from how they do. Instead of forcing customers to fit into how manufacturing operations manage time, leaders in digital transformation reshape operations to meet and exceed customers’ time expectations. Taking a time-based mindset completely changes the priorities for digitally transforming customer-facing processes, making the following often the most urgent to improve:

- Personalizing every aspect of the customers’ experience across online and offline channels by digitally providing contextual intelligence of their goals, needs, and preferences.

- Improving Configure, Price, and Quote (CPQ) accuracy, speed and responsiveness.

- Digitally enabling pricing so it stays consistent across any channel a customer uses, anytime.

- Orchestrating customer support across all channels using AI and machine learning to always stay contextually relevant to customers’ requests.

- Digitally transforming quality into a continuous improvement cycle by introducing customer-driven quality metrics and key performance indicators (KPIs).

- Capitalize on the greater contextual intelligence, insight and speed the Internet of Things (IoT) can infuse into customer-facing processes.

New Digital Business Models Are Manufacturing’s Future

A sure sign a new digital business model will succeed is when customers are quick to buy and grow more enthusiastic with every buying experience. Creating that level of momentum starts by becoming easier to do business with and overwhelming customers with value. Digitally enabling customer-facing processes gets the momentum started. Taking legacy systems and processes through a customer-driven digital transformation keeps the momentum going and scales production to flex and excel at new business models.

Digitally enabling legacy systems and processes only succeed if they are measured by customers’ success. Internal process improvements become the most relevant and valued when they improve customer experiences, help them achieve their goals, and drive future revenue growth. The following are examples of how manufacturers are digitally transforming legacy systems to support new digitally-driven business models:

- Design, produce, sell, and service products as customers view them, as lifecycles. The greatest disconnect in manufacturing today is the tendency to look at each phase of a product’s life as a separate ontology. This fragments product development and creates roadblocks to greater innovation. What’s needed is a more lifecycle-based approach to product configuration, one that relies on CRM, PLM and ERP systems orchestrated to a common product lifecycle goal. The graphic below shows how automotive manufacturers can digitally transform these three systems and create entirely new business models. Integrating back-office and front-office systems improve time-to-market for new models and time-to-customer on current orders.

- Integrating analytics and Business Intelligence (BI) at the machine- and shop-floor level to track everything from Overall Equipment Effectiveness (OEE), product configuration yield rates and engineer-to-order accuracy. The cornerstone of this new era of digital manufacturing is analytics and BIK-driven insights into every aspect of shop floor performance. What’s exciting about this area is how manufacturers on the leading edge of digitally transforming companies can translate shop floor data into financial results.

- Introducing real-time monitoring using the Internet of Things (IoT) across the supply chain, warehouses, production floors, distribution and selling channels to improve customer responsiveness. One of the best ways to exceed customer expectations and win loyalty is to be more responsive than they expect all the time. IoT is a pivotal technology for making that happen.

- Defining and delivering smart, intelligent products including those that generate products-as-a-service revenue will be the new normal in 2 years or less in many manufacturing industries. Digitally enabling manufacturing delivers an unexpected benefit: they’re able to transition faster to smart, connected product development and delight customers with innovative new solutions to their problems.

Digitally transforming quality into a continuous improvement cycle. The little-discussed aspect of digitally transforming manufacturing is how it’s possible to improve quality exponentially. It’s more important than any marketing or PR campaign because product quality gets broadcast in seconds across social media and product ratings sites. Digitally transforming manufacturing delivers higher product quality, which in itself is a reason to get started now.

Conclusion

Manufacturing is going through an era of digitally transforming itself from rigid to agile, flexible production strategies and processes. It is the era of digital manufacturing today, and the following five factors are the rocket fuel driving digital transformation across the industry today:

- Becoming collaborators in creation with customers by digitally transforming every aspect of production operations.

- Defining and delivering smart, intelligent products including those that generate products-as-a-service revenue will be the new normal in 2 years or less in many manufacturing industries.

- Digitally transforming quality into a continuous improvement cycle.

- Introducing Internet of Things (IoT) to optimize customer-facing processes and digitally transform legacy processes across every area of production.

- Define goals for digitally transforming manufacturing and measure them using lifetime customer value and the success of new business models.