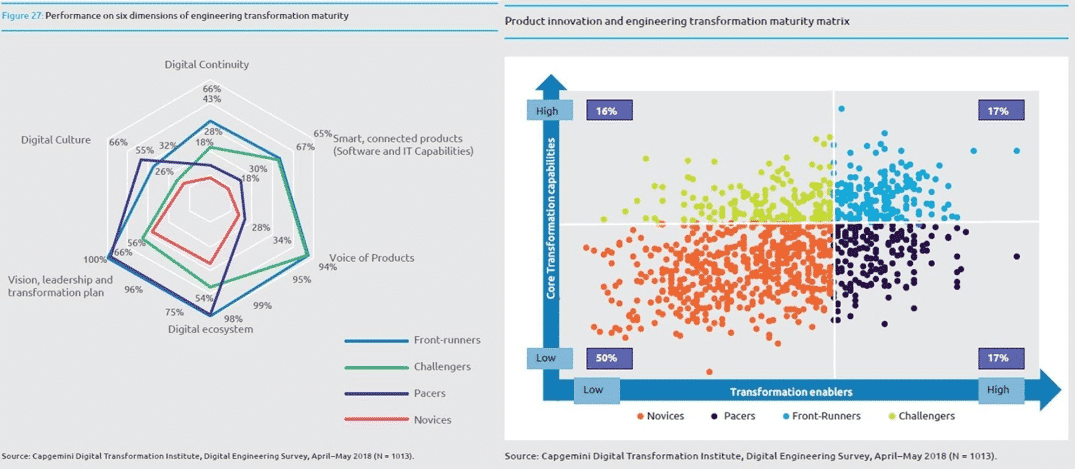

Capgemini’s Digital Transformation Institute’s recent research study Digital Engineering: The new growth engine for discrete manufacturers provides fascinating insights into how manufacturers are modifying their IT strategies, platforms, and spending to invest more in smart, connected products:

- Around 50% of manufacturers aim to spend more than €100M ($117M) in Product Lifecycle Management (PLM) platforms and digital solutions in the next three years.

- Spending on digitally-based PLM platforms and solutions are accelerating as budgets for maintaining legacy systems have dropped from 76% of IT spending in 2014 to 55% in 2017.

- The size of the connected products market globally will range between $519B to $685B by 2020.

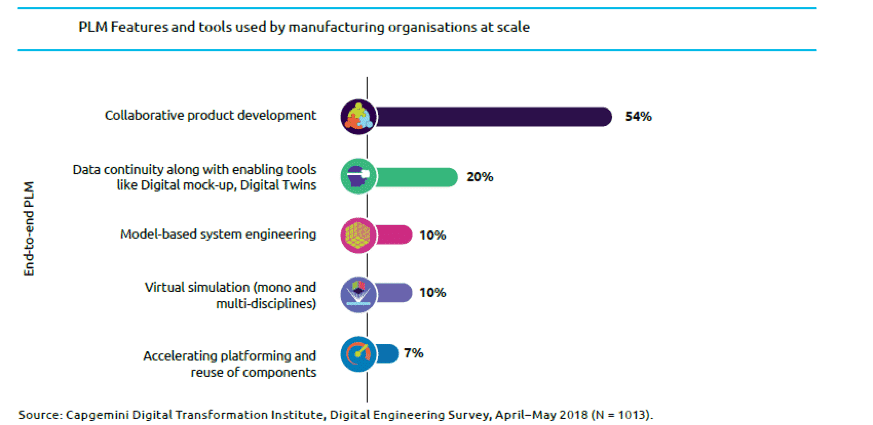

- Collaborative product development is the most popular use of PLM systems today, with 54% of manufacturers prioritizing this as their most relied on feature.

- Manufacturers who are successfully developing, launching and selling smart connected products are spending 10% more on end-to-end PLM and digital solutions with an average annual investment of 3.8% of revenues.

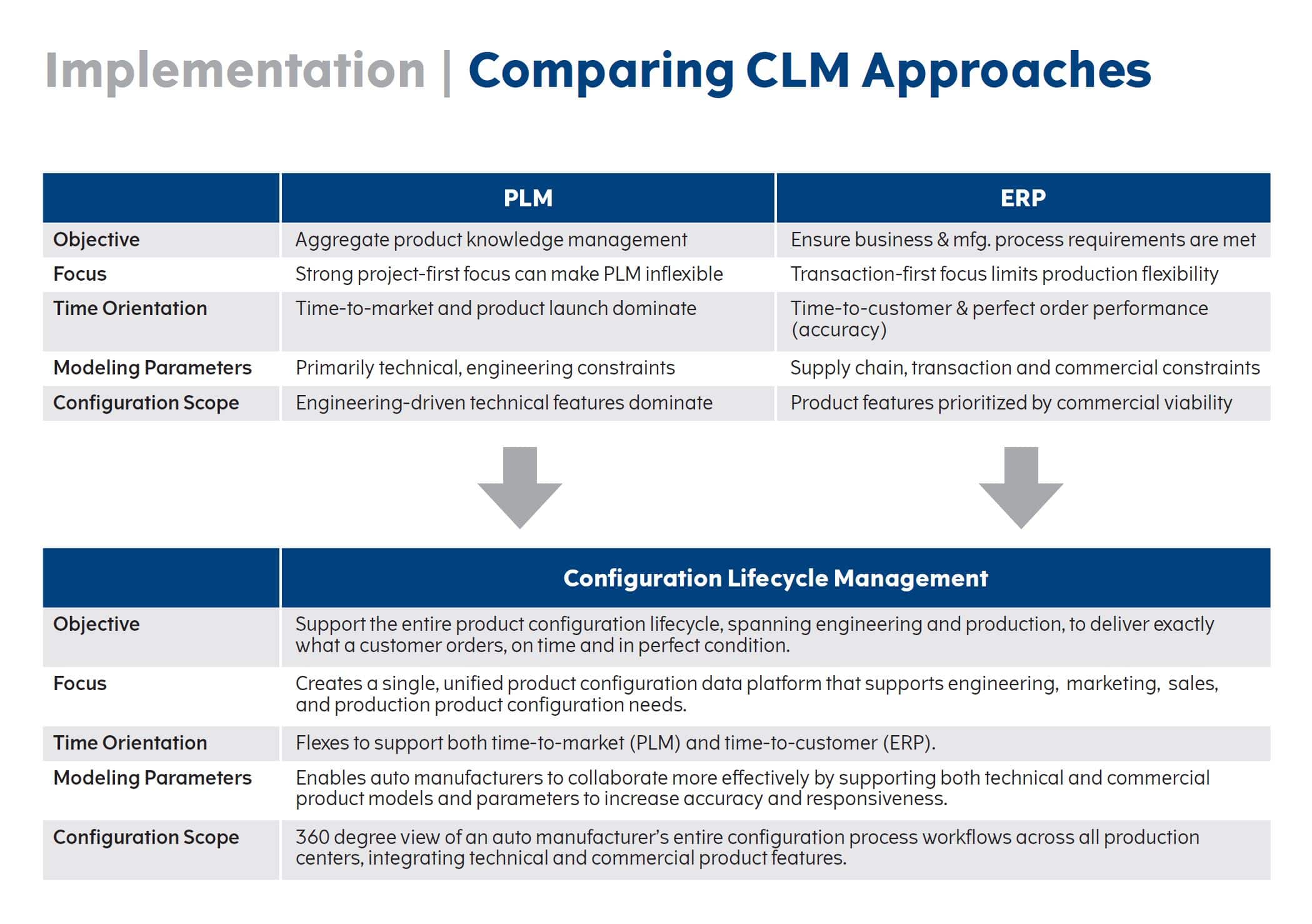

- PLM’s digital inflection point is enabling more manufacturers to manage product configurations across their lifecycles optimized with Configuration Lifecycle Management (CLM) platforms and supporting applications.