Closing the gaps that exist between customers’ changing needs for configure-to-order products and manufacturers’ ability to deliver them is where the Industrial Internet of Things’ (IIoT) greatest opportunities for growth are today. Manufacturers are transitioning from product-driven revenue to services and software, and making this strategy work they need to design and deliver smart, connected products

IIoT Platforms Are Enabling The Future Of Smart, Connected Products

The era of smart, connected products has arrived. Manufacturers predict 47% of all their products will be smart, connected and capable of generating product-as-a-service revenue by 2020. Capgemini estimates the size of the connected products market globally will range between $519B to $685B by 2020. Capgemini’s conservative estimate based on survey data and market analysis is that smart, connected products will add $518.9B or 6.63% to manufacturing value-added to the GNP of surveyed countries. In an optimistic scenario, where manufacturers accelerate their smart, connected product efforts, their combined efforts could potentially add up to $685.6B to manufacturing value added in 2020. Manufacturer’s investments in Industrial Internet of Things (IIoT) systems and technologies is predicted to reach $500B by 2020, with the value IIoT creates ranging as high as $15T of global GDP by 2030 according to Accenture.

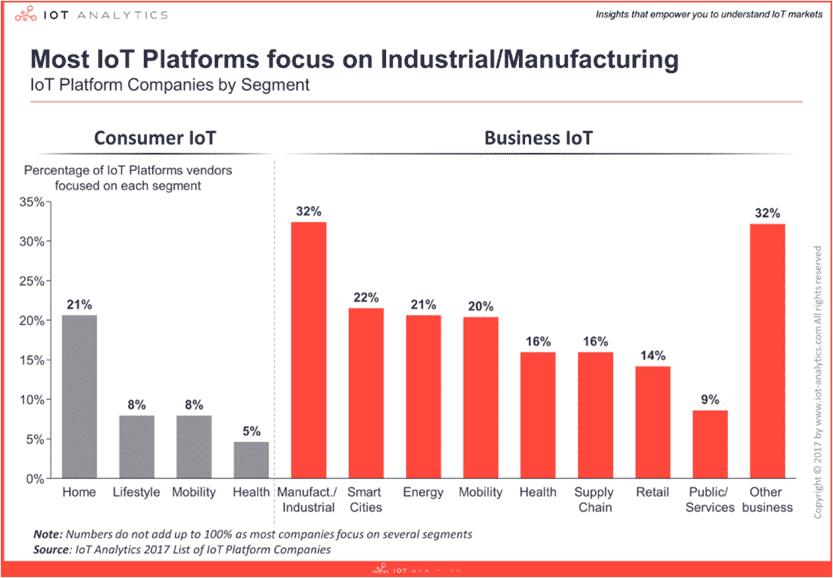

IIoT platforms enable and accelerate smart, connected product development and manufacturing by breaking down silos that slow progress. They’re also enabling diverse front-office systems including CRM and Configure-Price-Quote (CPQ) to integrate with and share real-time data with ERP, PLM and CAD systems. Each of these systems runs at their clock speed or cadence, and each is vital to successful product configuration strategy being achieved. Engineering needs PLM & CAD systems to develop new smart, connected products and manufacturing need ERP to manage all operations from the shop floor to the top floor. IIoT platforms are making it possible to take a true Configuration Lifecycle Management (CLM) approach to smart, connected products. IIoT platforms are purpose-built for manufacturing as the graphic below illustrates.