What Is a Product Configurator?

Learn Why Choosing the Right

Configuration Solution Matters

Having a good product configurator can be the difference between getting orders right, or having costly errors in production. Determining the size and type of configurator your company needs is key. A product configurator that is too weak can put the company at risk by introducing errors in the configuration sent to manufacturing.

Before you can decide on what type of configurator you need, it is necessary to understand what product configurators are and how they work. This blog post will outline the benefits of using a product configurator in complex products and environments that will help you make an informed decision.

A Product Configurator is a software tool that allows customers, sales teams, or engineers to customize and visualize complex products or services based on a set of predefined rules and options.

Product Configuration is an interactive process where the user chooses a feature, which is validated via a configuration rules engine, before allowing the user to make the next choice about the remaining features on their product.

The seeming simplicity of this process hides the complexity in construction and validation of the rules used to drive the product configurator.

What’s the Innovative Technology Behind Configit’s Solution?

In this Tech Talk, Tom Davidson, Senior Sales Engineer, highlights the crucial role a powerful configuration engine plays in managing complexity and ensuring smooth operations.

A product is configurable if it is capable of being customized when ordering, or it can be rearranged or adjusted post-production.

For the customer, products with multiple features (or “variants”) can be configured based on needs or wants (e.g. color, heated seats, or trim options in a car).

For the manufacturer, proper configuration ensures that the product lives up to regulatory purposes such as the voltage an electronic device runs at (e.g. 220V for Europe or 120V for The United States). This is a detail we as customers do not want to consider when buying an electronic product. We expect it to come with the correct adapter for our geography.

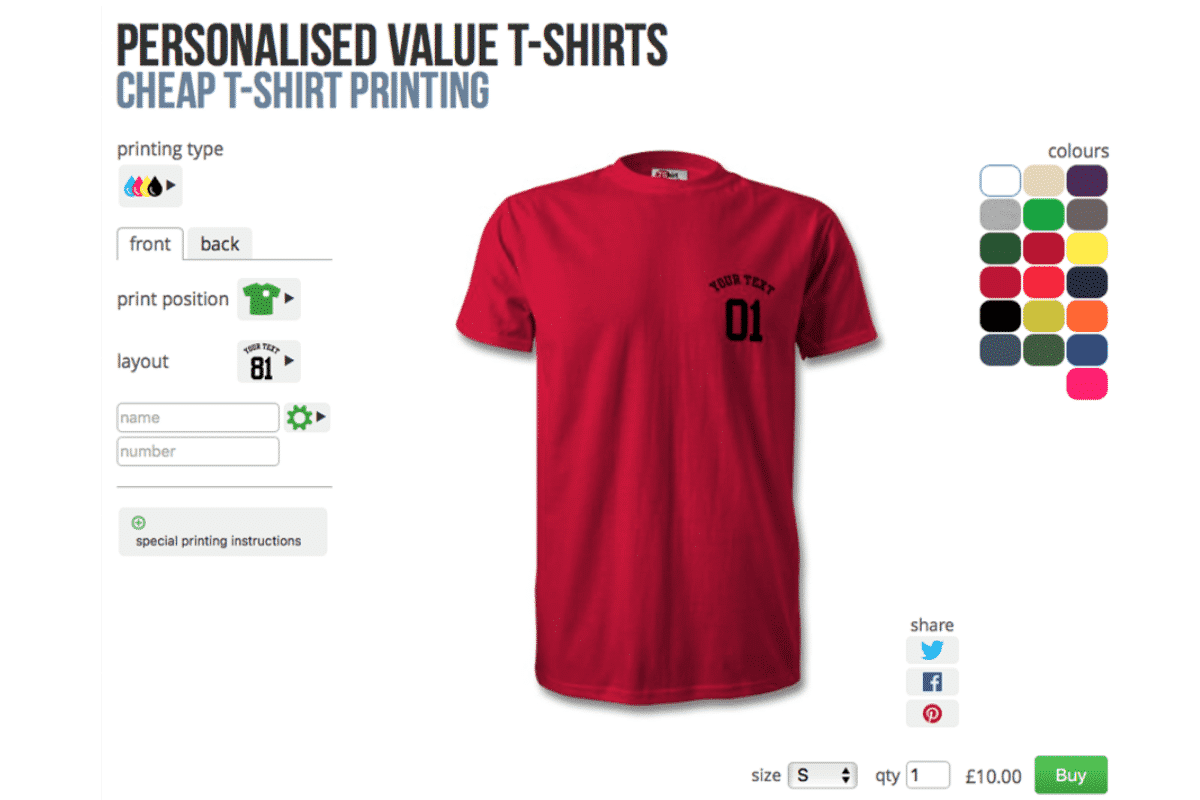

A simple example of a product configurator is a clothes shop that allows you to tailor your own t-shirt. Their website would provide options to choose from a variety of features before finalizing the purchase, such as color, sleeve length, material, size, style, artwork/prints, etc.

A t-shirt configurator that has four features to consider is a relatively simple configuration to solve. But for products that have more than 50 features, the scenario quickly becomes more complex.

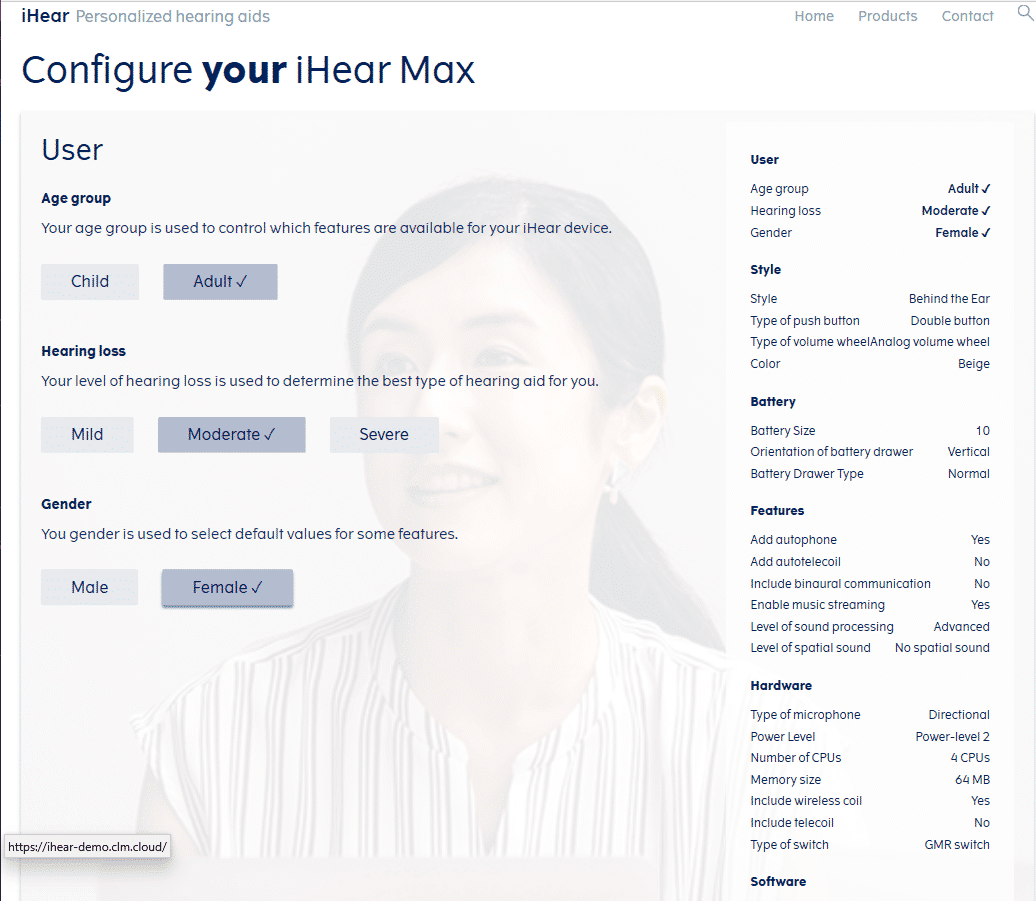

Take a hearing aid as an example (feel free to test it out yourself in this demo). In configuring the hearing aid, choices must be made regarding “standard” options such as battery type, preferred color and placement in/around the ear.

Some of these choices may influence other choices downstream in the configuration process. For instance, the choice of memory size impacts choices for telecoil and microphone.

A good product configurator will guide the user through the configuration process.

In this example, the amount of memory in the hearing aid is a choice that influences several different features: If you want a telecoil (an antenna for your ears that receives magnetic waves and converts them to sound), then you cannot have an omnidirectional microphone in the hearing aid, only a dual directional, and you can only get 64MB memory and 4 CPUs. Because this hearing aid configurator is based on rules that explain these correlations, you as the user receive a small pop-up notification informing you that the choice about to be made has an impact on the following features.

See How Configit CLM Solutions Can Fit Your Needs

Our experienced Configuration Lifecycle Management (CLM) specialists are ready to show you the benefits you can achieve.

Contact us today to schedule your free demo.

Contact us today to schedule your free demo.

Many of the configurators used in the manufacturing industry today cannot provide the security of knowing all configurations are legal, as they are based on older configuration technology. This insecurity can put the company at risk. Many manufacturing companies of complex, configurable products attempt to mitigate this risk by having engineers check all proposals before sending them to a customer; a process that is time-consuming and costly.

This online hearing aid configurator is an example of modern configuration technology. Using a compilation of the full solution space of the product (all the features, rules and conditions), the product configurator has the knowledge of all legal configurations of the product and can thus inform the user when a choice would result in an illegal combination of features.

With this level of configuration technology, the product configurator will produce 100% legal products, making the process much smoother and safer for both customer and manufacturer.

Learn more about the technology behind this configurator by visiting our Virtual Tabulation® technology page.

Daniel Joseph Barry is VP of Product Marketing at Configit. Dan Joe has more than 30 years of experience in engineering, sales, marketing, product management and strategy roles within IT and telecom companies.