The Virtual Tabulation® approach offers a number of unique business benefits, five of which are:

- Full guidance

- Performance

- Correctness

- BOM Validation

- Optimization

We will cover each of these in more detail in the following.

Full Guidance

The compiled-based approach enables the user, without technical knowledge of the model, to optimize and locate a valid configuration. Expert users don’t need much guidance other than a validation of their choices. But, if you’re a non-expert, you need the full guidance of a configurator to prevent you from being led down a dead end path. Such trial and error will make the experience error-prone and frustrating.

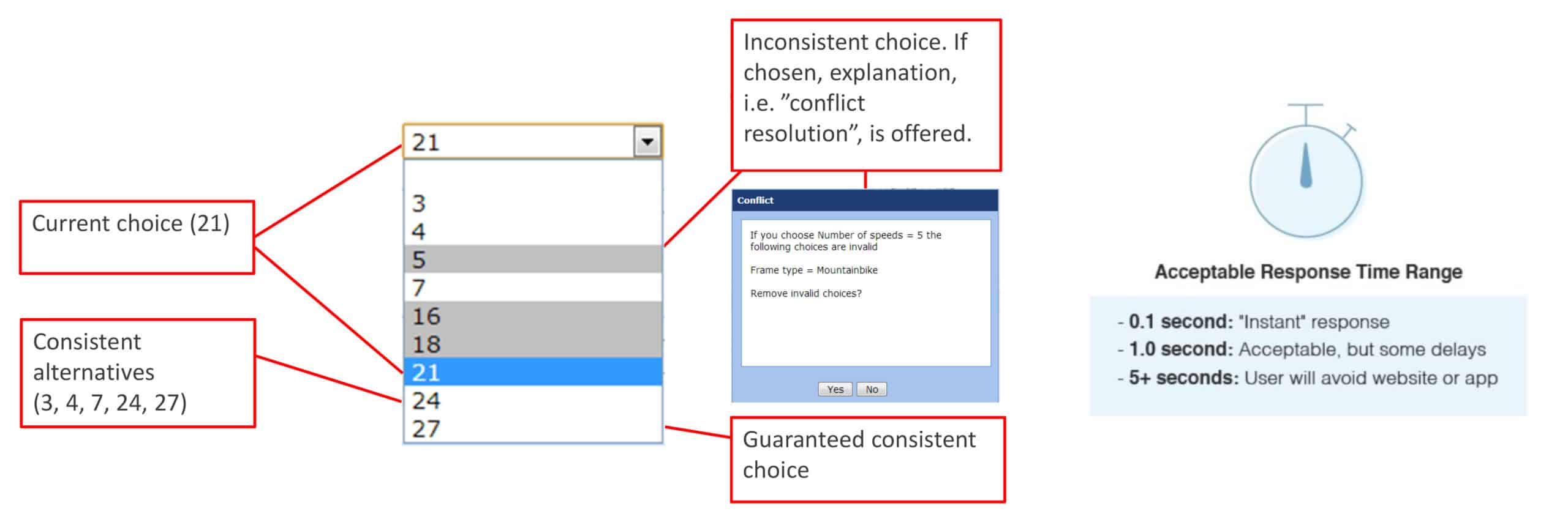

The full guidance configurator will guide and inform you of other consistent choices when you choose a parameter, such as the number of gears on a bicycle. Non-valid combinations are greyed out, but still selectable, and if selected, the configurator explains the consequence and highlights the conflicts needed to solve towards a valid configuration.

Performance

If your configuration engine doesn’t answer efficiently and quickly, it will never get user acceptance. The typical guidelines for acceptable performance is less than a second from selecting a choice to receiving the response. Performance around 0.1 second (or 100 milliseconds) feels instantaneous. But it’s around one second where people’s patience stops.

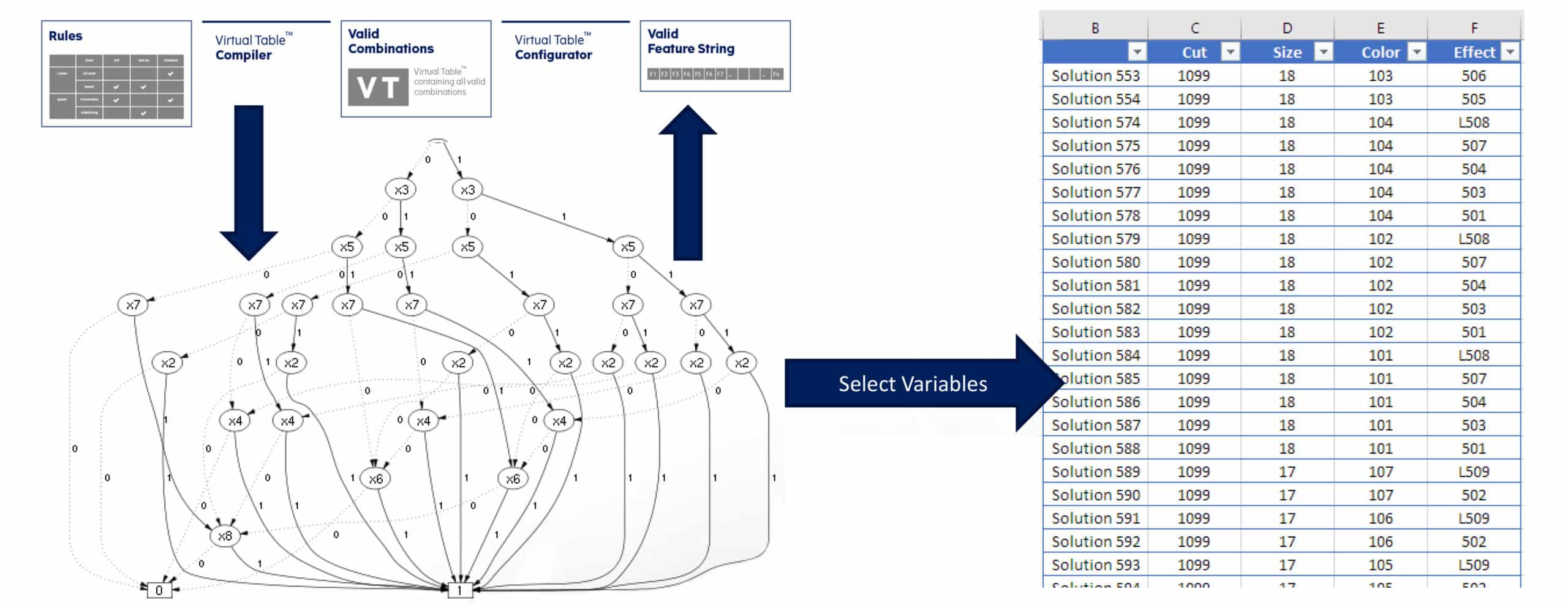

With a compiled approach, the difficult problem is solved once, and guiding the user to the consequence of his choice will be like a look-up in a table, resulting in fast interaction.