When I speak one-on-one with CIMdata clients as they wrestle with Configuration Lifecycle Management (CLM) and other enterprise-level technology-based initiatives, I am often asked “what” and “why” in addition to the usual queries about “how” and “when will we be done.”

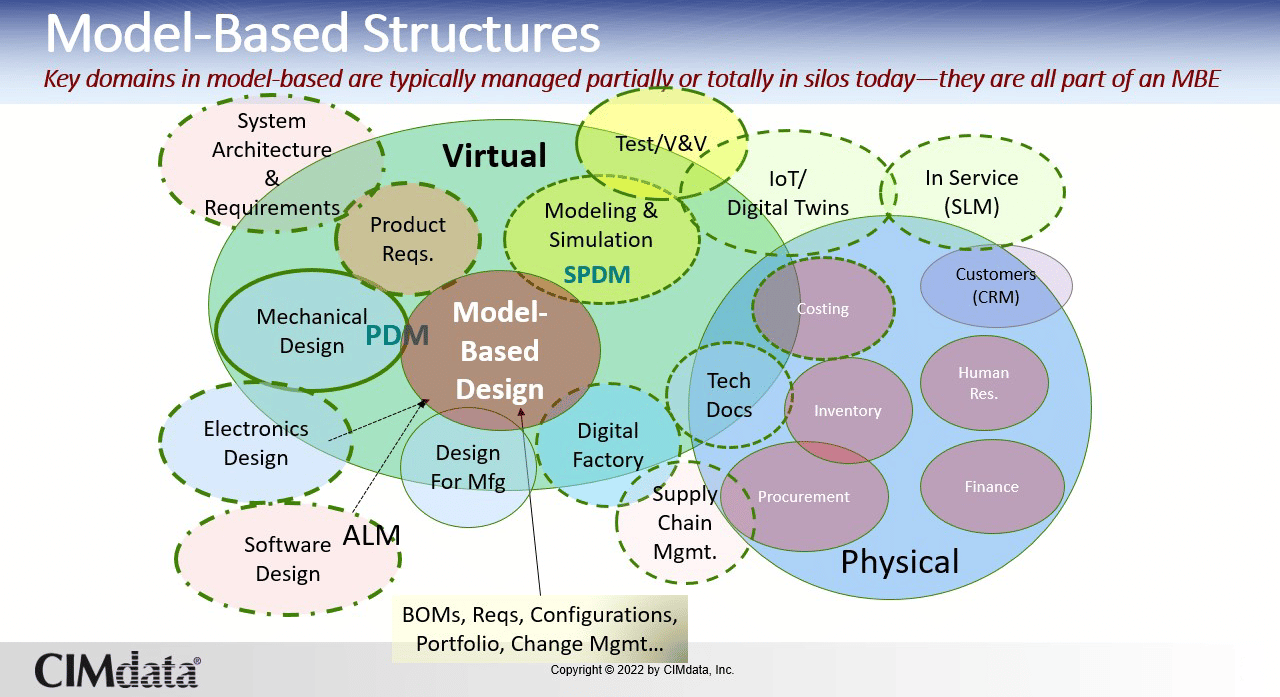

More and more, the “what” and “why” questions are about Model-Based Structures (MBS’s), which are the information foundation for Model Based Systems Engineering (MBSE), and whether coagulating the enterprise’s information into models is important and what configuration management’s role should be. Given the effort and cost involved, they ask, are models really any better than the clusters of data each engineering discipline develops, maintains, shares, and secures?

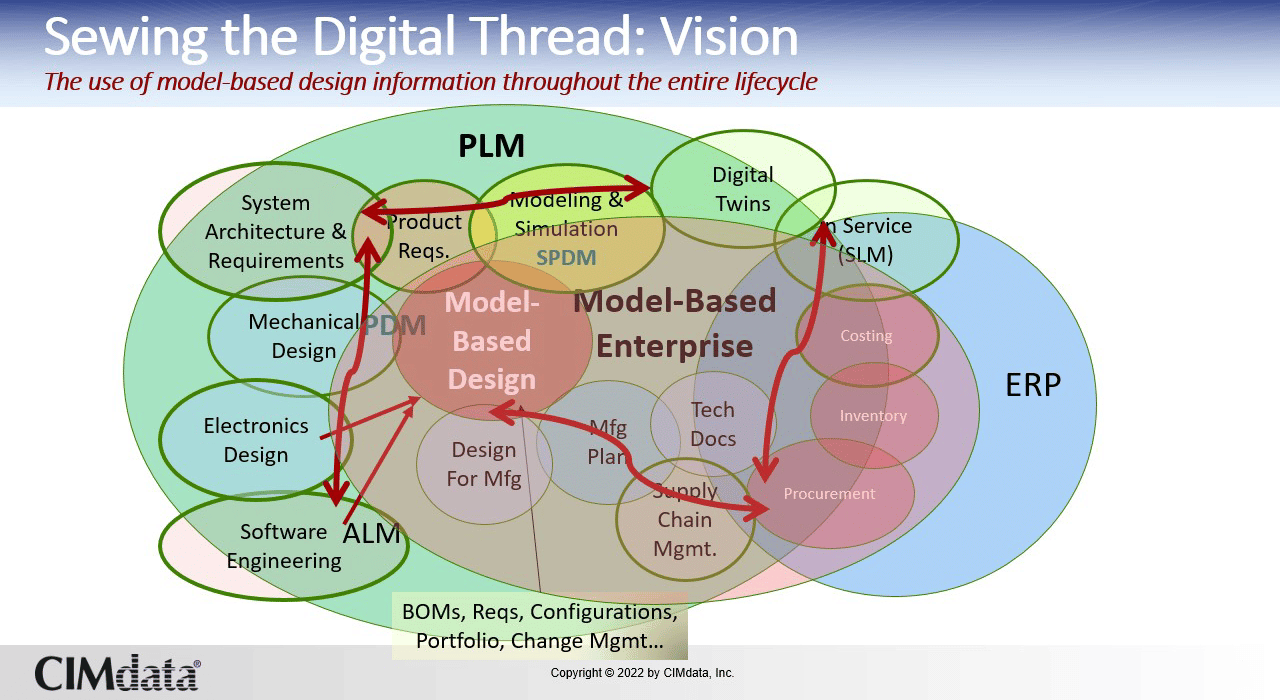

Fig.1 – Source: CIMdata, Inc.