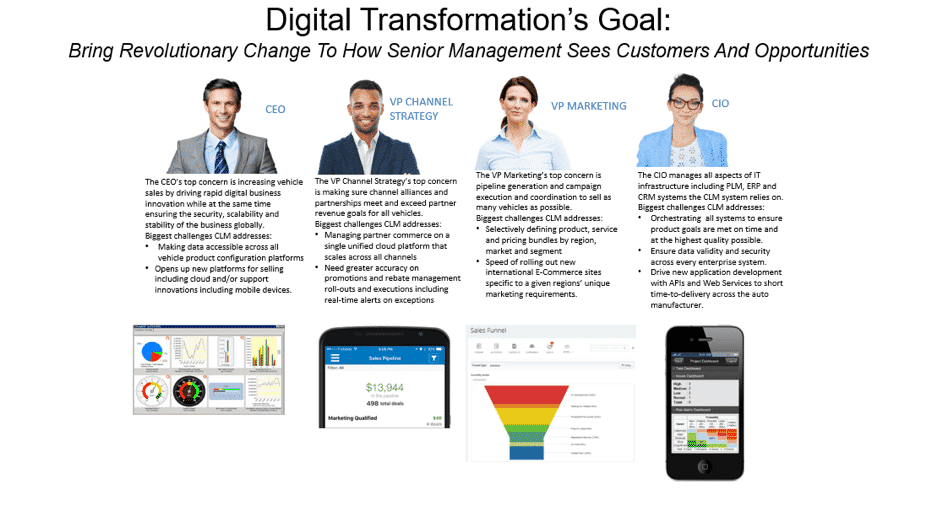

Every business needs to keep growing by innovating or risk seeing their core markets shrink by 60% or more in three years due to rapid advances in digitization according to IDC. Digital technologies are enabling entirely new ways of optimizing existing business strategies & models and growing launching new ones.

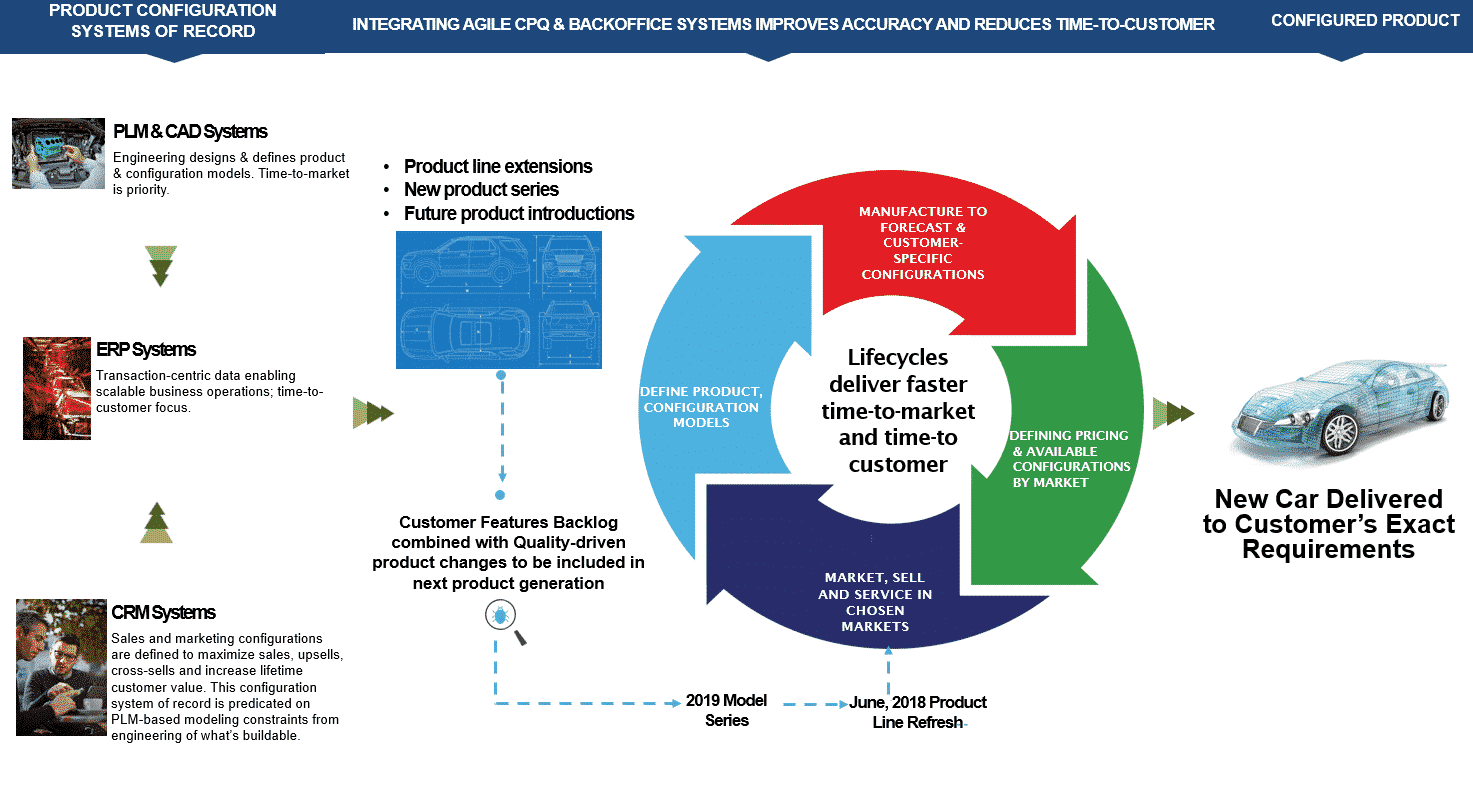

The following market forecasts and survey results reflect how integrating front-end, and back-end processes are catalysts of growth for manufacturers today and in the future:

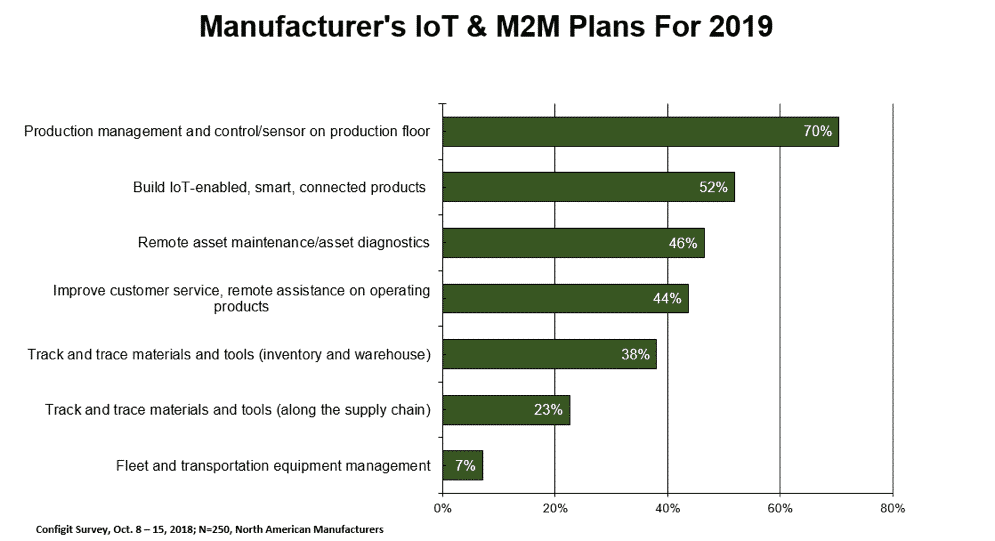

- By 2021, the effectiveness of manufacturing IoT initiatives will be tracked by business outcomes continuously through their life cycle, up from less than 20% today.

- 25% of midsize organizations engaging in Industrie 4.0 strategies will collaborate in cross-industry ecosystem initiatives by 2020, up from 10% in 2018.

- 30% of manufacturing companies with more than $5B in revenue will have implemented Industry 4.0 pilot projects using blockchain by 2023, up from less than 5% today.

- By 2023, 30% of Industrie 4.0 projects will also be using blockchain technology.

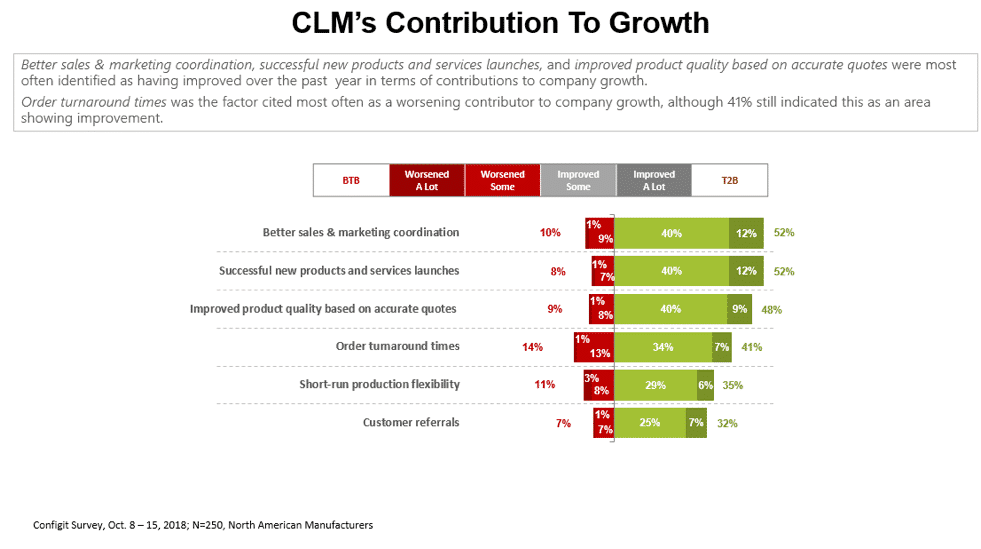

- 62% of North American manufacturers integrating their Configure, Price Quote (CPQ) system to a CRM system alone are growing at least 5% a year based on a recent Configit survey.

Competing smarter, faster and with greater intensity in the future starts with the decision to digitally transform manufacturing today. Based on visits with manufacturers I’ve seen where digital transformation is paying off the greatest today. It’s immediately improving existing products with greater insights, reducing Cost of Goods Sold (COGS), Sales, General & Administrative (SGA) and revolutionizing customer experiences. Digitally optimizing inventory levels, production yields, and physical asset uptime while generating cash from operations are how many manufacturers are paying for digital transformation today.