One of the areas where manufacturers are facing major challenges, which requires a digital transformation strategy, is managing complex product configuration. A Configuration Lifecycle Management (CLM) solution provides the ability to manage this complexity and scale as that complexity increases.

The challenges that manufacturers of complex products face involve continuously shrinking product lifecycles and increased customer demands for customization and variety. Products themselves include more software allowing configuration after purchase. Potential configuration options need to be carefully designed and considered up-front and strictly managed once in the field. Service personnel need access to accurate and up-to-date information on configuration options in order to service products effectively in the field.

CLM solutions, such as Configit Ace® powered by Virtual Tabulation®, manage the rules governing product configuration options, providing a single-source-of-truth on which product configurations are possible to manufacture and order. CLM solutions are dynamic and continuously updated with real-time information on component and material availability so that options presented are valid and actionable.

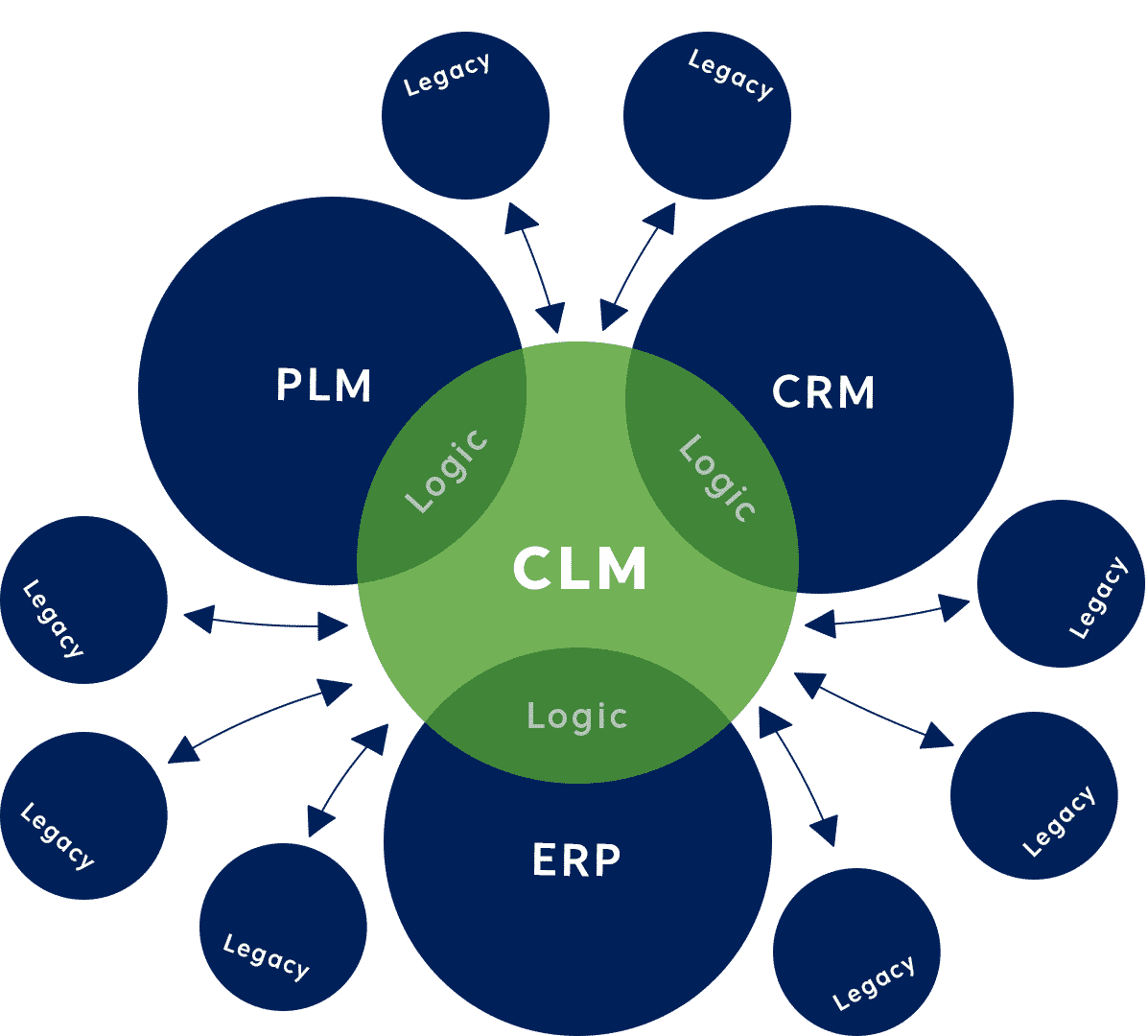

CLM is naturally a cross-functional solution that can provide a platform for collaboration between otherwise siloed organizations and functions. For example, Product Lifecycle Management (PLM) solutions define how products are architected and manufactured. However, definitions of product configuration options can be static and confined to the PLM system. By combining PLM with CLM, it is possible to support a richer and dynamic variety of configuration options and make them available to other functions.

The manufacturing organization can access the real-time information in CLM to ensure that products are manufactured with the latest information on vendor components and materials so production can progress without delay. The sales organization can access the same information to understand which options are available to order for customers. Sales can also add configuration rules that are important to the sales process, but not necessarily important to product managers, such as financing options or payment terms. Finally, the service organization have access to the latest information on product configuration options including updated information on component options for replacement.

While there can be a formal owner of the CLM solution, each function can access the information, define their views so only information relevant to their function is provided and even add configuration options and rules to the CLM solution, which are important to their functions.

CLM provides a strategic platform for collaboration between all of these functions so that product engineering, manufacturing, sales and service can act immediately and with confidence safe in the knowledge that the information available is accurate and up-to-date. CLM thus provides the first step towards breaking down the barriers to digital transformation.