Manufacturers growing the fastest today approach digital transformation entirely differently than their slower-growing peers. A recent survey of 250 North American manufacturers by Configit found the following:

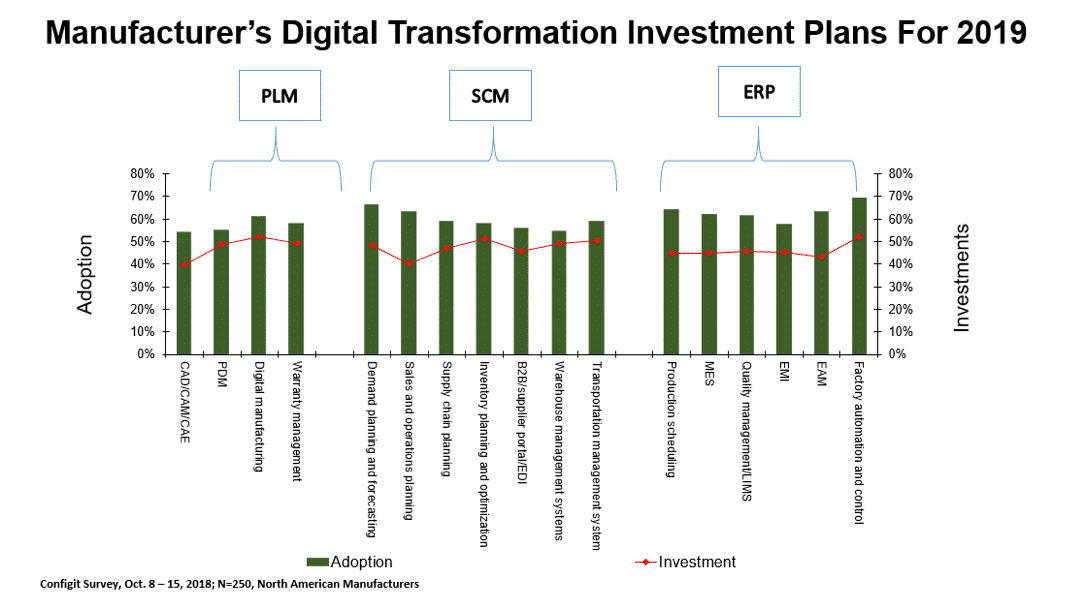

- Manufacturers growing 10% a year or more excel at orchestrating PLM, CAD, ERP, and CRM, digitally transforming how products are defined, built, sold and serviced.

- High growth manufacturers concentrate on how they can reduce time-to-market and achieve perfect order performance by integrating systems that accelerate new product development and improve on-time delivery rates.

- On average, manufacturers growing 10% a year or more have four or more systems integrated, while those growing 10% a year or less only integrate with 1 or 2 systems at the most.

- Realize that making quality management, compliance and customer feedback the core of digital transformation efforts is essential if they are going to stay on track and keep accomplishing challenging growth goals.

- Have an aggressive API strategy that concentrates on how to streamline ERP, PLM, CAD and CRM systems with enough agility to flex to customers’ changing needs.

- Manufacturers growing 10%, or more a year succeed at integrating PLM, CAD, ERP, and CRM to create a Configuration Lifecycle Management (CLM) platform. Their CLM platforms enable them to take a model-based approach to product innovation, giving customers greater convenience, collaboration, and control over their build-to-order products.