Bottom Line:

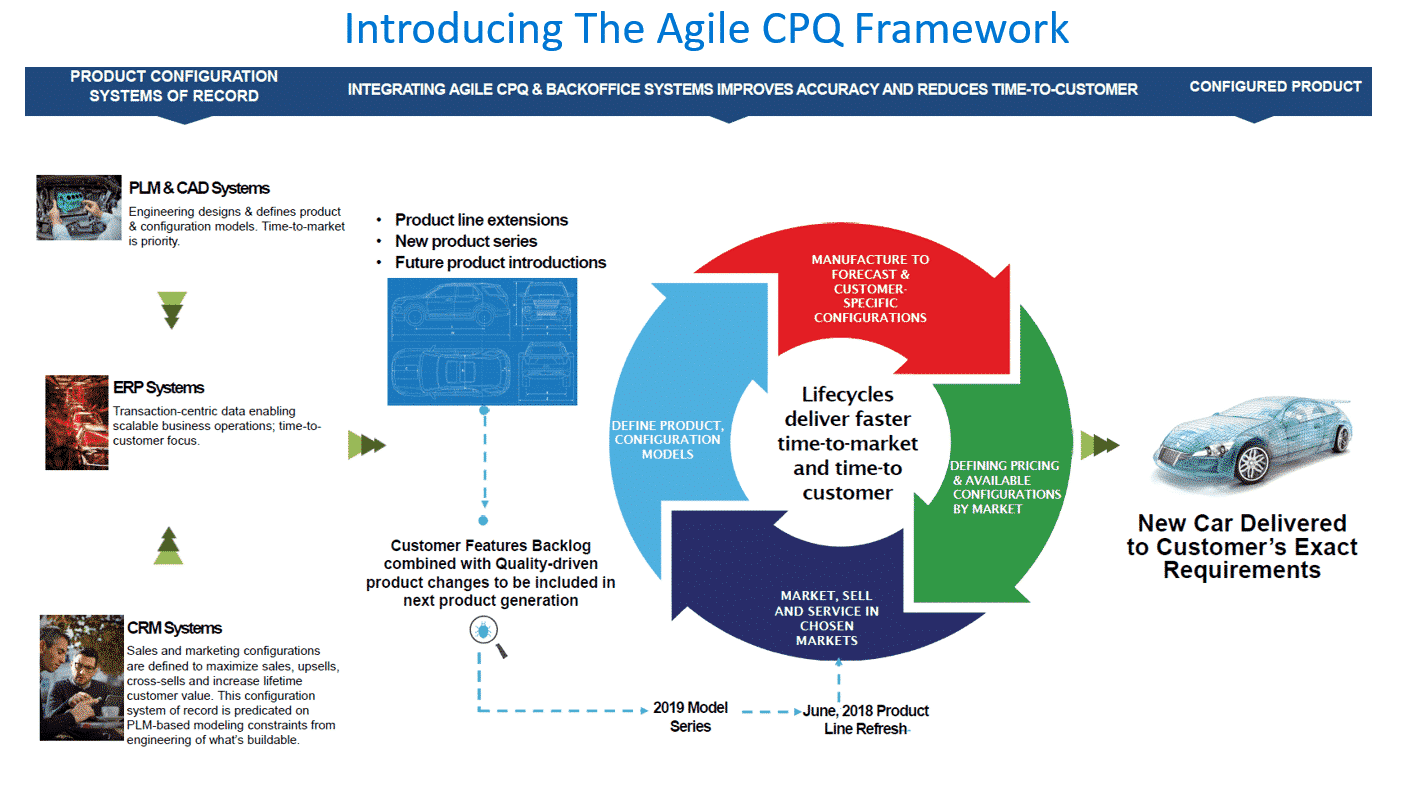

The greater freedom customers have to customize products, the greater the opportunities to grow sales. Providing them the freedom they want starts with an Agile CPQ strategy integrating CAD, CRM, ERP and PLM systems on a single configuration thread.

The single greatest roadblock to driving more product revenue is the wide disconnect between what customers want to buy, what engineering says is possible to build, and what manufacturing can deliver. It’s time for every manufacturer to realize that customer perceptions are their new reality.

Relying on IT platforms and enterprise applications built for uniformity first, supporting only basic workflows, lacking integration options and designed for now outdated ways customers want to buy are driving the gaps wider between customers and manufacturers. By taking an Agile CPQ approach to unifying marketing, selling, engineering and manufacturing on a single configuration thread, manufacturers are able to keep growing and close gaps between them and their customers.