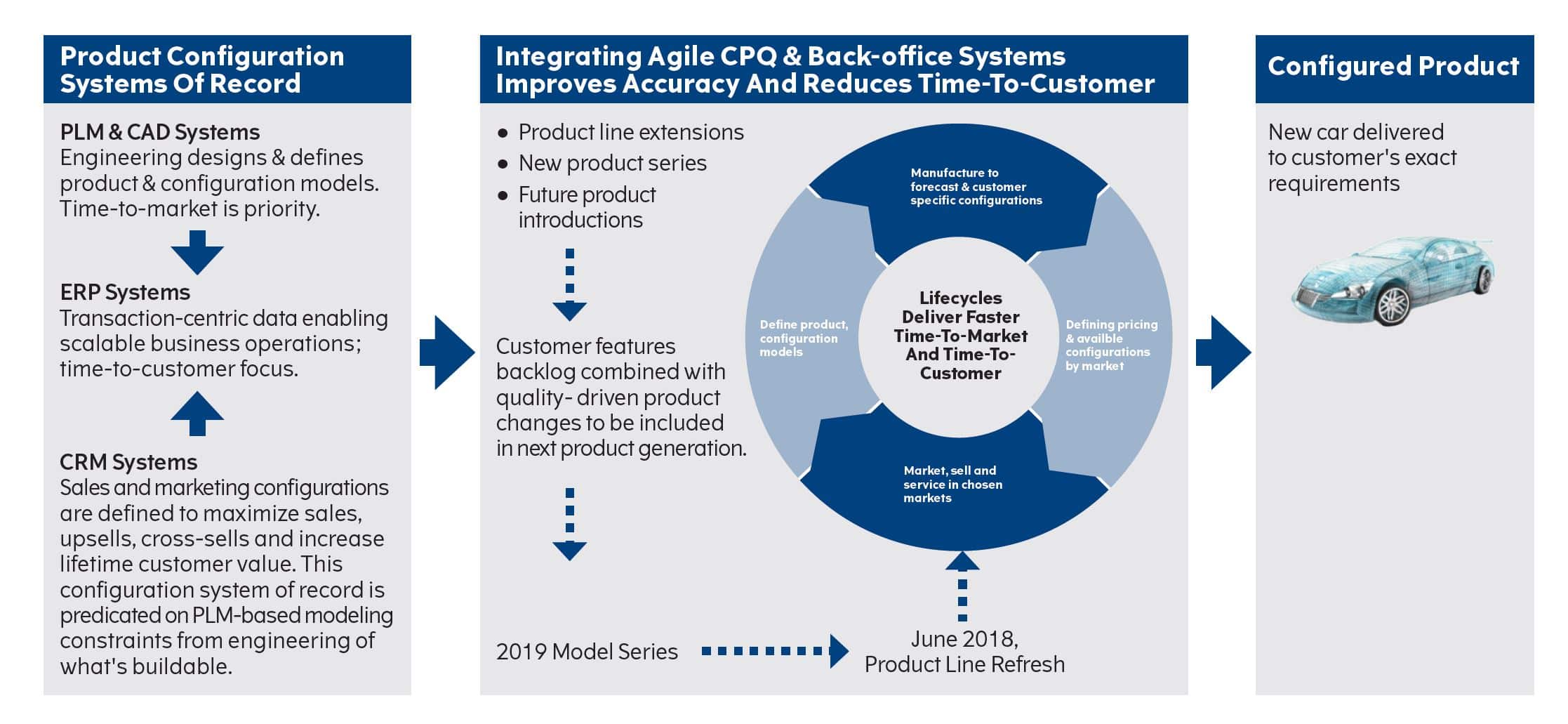

Recognizing that customers are co-creators in the creation of new products and want the freedom to define custom configurations at a competitive price, manufacturers are quickly adopting digital transformation. Defining and excelling at a digital transformation strategy needs to start with the following:

- Product configurators need to reflect how customers prefer to buy

- Encouraging customers who want to co-create by providing control over options

- Perfect consistency across all selling channels wins customer loyalty

- Customers think regarding product lifecycles, so systems need to reflect that

- Re-think product quality metrics and put the customer-centric ones first

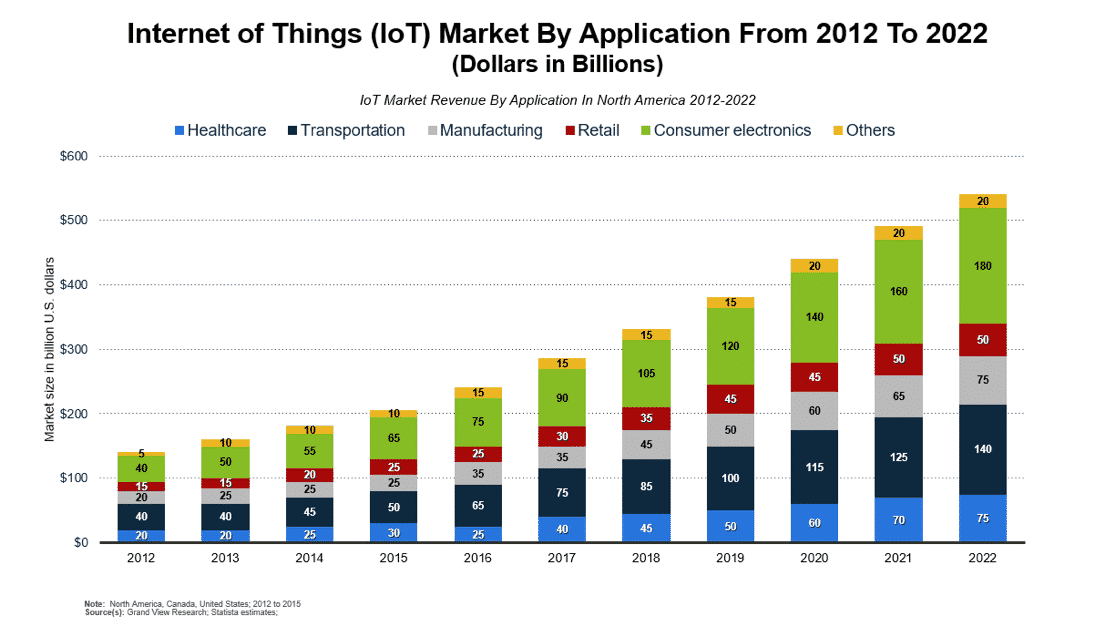

Every manufacturer is in a race to gain greater market share, improve product quality, hold onto the customers they have and win new ones. Manufacturers whose core DNA is based on product configuration strategies and who can flex from assemble-to-order to engineer-to-order are ideally positioned to grow in this era of smart, connected products.