Configuration Lifecycle Management (CLM):

A Discrete Manufacturing Solution for Mass Customization

The demand for customized products and services is growing. Customers want products that are tailored to their specific needs. This is where mass customization comes in.

Mass customization is a manufacturing strategy that combines the flexibility and personalization of custom-made products with the low unit costs associated with mass production. This strategy allows manufacturers to produce products that are tailored to the specific needs of individual customers, while still achieving economies of scale.

Using a mass customization solution, manufacturers can:

- Meet the demand for customized products and services

- Increase customer satisfaction

- Reduce costs by streamlining the manufacturing process and by reducing waste

- Improve flexibility

Mass customization is common in specific types of manufacturing, such as apparel, eyewear and personal computers. However, the complications grow when mass customization is applied for discrete manufacturing in an industrial setting.

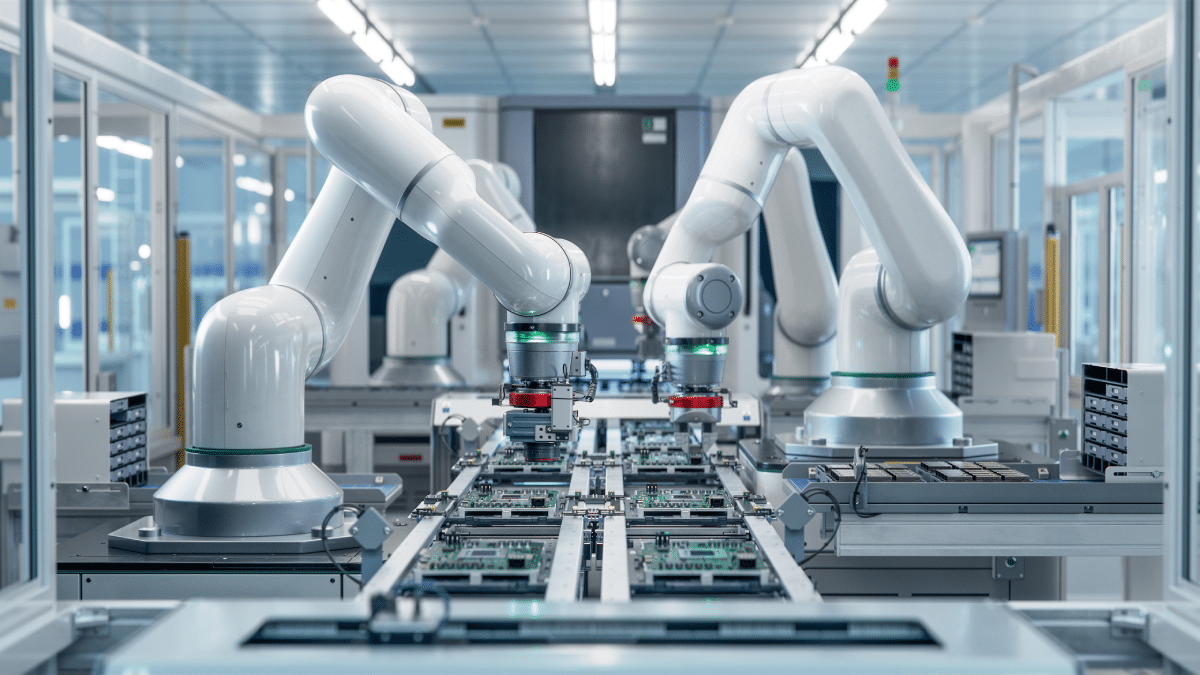

Discrete manufacturing is one of the most prevalent manufacturing processes that utilizes a production or assembly line. This production method creates finished products with raw materials or parts you can assemble and disassemble. Manufacturers using this production process typically assemble parts to create subsystems or finished products.

In discrete manufacturing, several workstations throughout the production line produce distinct components, parts, materials, or subassemblies, to be put together at the end of the production cycle to create the final product. Additionally, these final products may be disassembled into their components and recycled.

These resulting products are easily identifiable and differ greatly from process manufacturing where the products are undifferentiated, for example oil, natural gas and salt.

A key component of discrete manufacturers is their reliance on strong back-office systems. Enterprise Resource Planning (ERP), Product Lifecycle Management (PLM) and Configure Price Quote (CPQ) systems are utilized to keep track of all features, components and parts of each product combination.

For manufacturers wanting to provide customers with the ability to customize the final products, these enterprise systems must work in unison, sharing critical data across their siloed functions.

This is where Configuration Lifecycle Management (CLM) can be applied as a discrete manufacturing solution. By connecting the back-end systems of ERP, PLM and CPQ via the product configuration data, CLM creates a shared source of all valid product configurations. This validated product configuration data is then fed back into the respective functions – Sales, Engineering, Marketing, Manufacturing and Service.

Referenced by Gartner as a critical component in the design, manufacturing, sale and service of complex, configurable products, CLM delivers the scale manufacturers need to increase productivity, improve quality and drive innovation[1].

The result is that the customer is presented with only valid options when configuring their desired product and can choose which feature is most important to their individual goals. Whether that is, in the case of a vehicle, fuel efficiency, drive range, color, or fuel type.

Beyond the point of sale, these configurations can also be used by manufacturers to perform maintenance more efficiently, as they know the exact specifications, features and options that are contained in the product. This also provides a significant opportunity for sales to suggest upgrades that will be compatible with the customer’s product.

Over time, these manufacturers can analyze the data gathered through the Solution Space of all possible valid configurations to develop modules of often-ordered product features and combinations, transitioning from a cumbersome engineer-to-order process to a more streamlined configure-to-order solution.

Discrete manufacturers create, build and deliver products for their customers from orders they receive from different channels, either internal sales, through resellers, or from customer self-service portals.

To stay competitive, these manufacturers must meet their customers where they are with the products or services that are in demand no matter the channel.

Using a CLM solution, discrete manufacturers can:

- Improve the overall buying experience by providing customization choices

- Accelerate sales by reducing friction of errors

- Increase brand loyalty

- Increase cross- and up-sell opportunities

- Change service from a cost center to a revenue center

Read more about the benefits of Configuration Lifecycle Management (CLM) as a solution for discrete manufacturing.

Simplify Complexity with Configuration Lifecycle Management (CLM)

Discover the complexity challenges it helps your organization address, and how to get started.

About the Author

Henrik Reif Andersen is the Chief Strategy Officer and co-founder of Configit, the global leader in Configuration Lifecycle Management (CLM) solutions and a supplier of business-critical software for the configuration of complex products. He holds a doctorate in computer science from the University of Aarhus and has more than 25 years of experience in IT development and research.

Notes:

[1] Gartner®, Hype Cycle™ for Advanced Technologies for Manufacturers, 2023, by Marc Halpern, Sudip Pattanayak, Christian Hestermann, Alexander Hoeppe, Published 25 July 2023.

GARTNER is a registered trademark and service mark of Gartner, Inc. and/or its affiliates in the U.S. and internationally, and HYPE CYCLE is a registered trademark of Gartner, Inc. and/or its affiliates and are used herein with permission. All rights reserved. Gartner does not endorse any vendor, product or service depicted in its research publications and does not advise technology users to select only those vendors with the highest ratings or other designation. Gartner research publications consist of the opinions of Gartner’s Research & Advisory organization and should not be construed as statements of fact. Gartner disclaims all warranties, expressed or implied, with respect to this research, including any warranties of merchantability or fitness for a particular purpose.