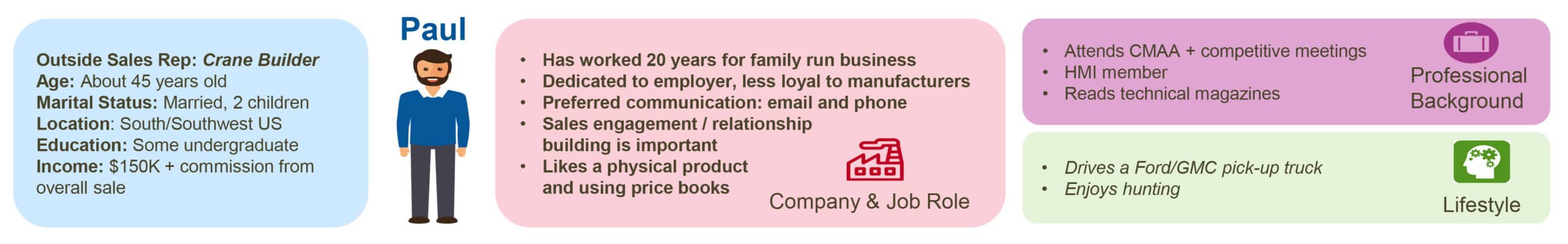

As a global manufacturer of material handling and motion control products, Columbus McKinnon (CMCO) is the second largest hoist company in the world and home to numerous brands, including Yale Hoists, Stahl Crane Systems, Camlok and more.

CMCO’s products fall into three core areas:

Industrial Products

Consists of both standard products and configure-to-order products, including manual products such as leather and hand-chain hoists, electric chain hoists, air hoists, rigging, clamps, and industrial winches.

Crane Solutions

Includes larger wire rope hoists, crane systems, and all the elements that go on an overhead crane, such as stoning, conducting wire rope, handlings, and drive systems, as well as jib and close track workstation cranes. Some products are standard, while a large percentage are both configured and engineered-to-order.

Engineered Products

Comprises linear and mechanical actuators, and rail and road business-related products such as train carriages. These products are also a mix of standard products, configure-to-order and engineered-to-order.

In addition to making these products, CMCO focuses on helping their customers solve business problems by helping them develop and implement complex applications.