- Gartner predicts the CPQ market will continue to grow at a compound annual growth rate (CAGR) of 20% through 2020 in the Market Guide for Configure, Price and Quote Application Suites.

- Cloud-based CPQ revenue is now approaching the majority of the market and will accelerate through 2020, redefining the landscape of this market according to Gartner’s Market Guide for Configure, Price and Quote Application Suites. As of 2015, the market was valued at $157B and is projected to attain solid double-digit growth through 2020.

- 83% of sales professionals are using some form of a Configure-Price-Quote (CPQ) system today according to a recent study by Accenture Interactive in their study Empowering Your Sales Force: It’s Not Just Automation, It’s Personal.

The Secret To Being Customer-Driven Is A Scalable CLM Strategy

Configuration Lifecycle Management (CLM) Scales Selling Beyond CPQ’s Limits

The complexity and pace of selling are accelerating across the spectrum of global manufacturers today. The greatest challenge for many is designing greater speed and scale into their selling systems while enabling real-time integration with Customer Relationship Management (CRM), Enterprise Resource Planning (ERP) and Product Lifecycle Management (PLM) systems. Integrating these diverse systems unleashes the single greatest asset the company has; the depth and breadth of customer history, insight and knowledge. It’s time for manufacturers to realize that relying on long-standing systems of record based on business models of the past aren’t scaling well for today or the future. Integrating CRM, ERP and PLM systems is the catalyst to create an entirely new system of record to deliver greater revenue growth while managing product configurations over their lifecycle. Configuration Lifecycle Management (CLM) takes the most valuable customer data in CRM, ERP and PLM systems and transforms it into a catalyst for sales growth. By creating a new customer system of record based on these three systems’ most valuable data, CLM systems deliver the following benefits:

- Turning PLM data into profits. Turn Product Lifecycle Management (PLM) data and customer insights into a revenue growth and profitability accelerator.

- Go from tactical to the strategic in selling strategies and quit competing on price so much. Instead of always trying to win deals on price alone, add more value by using transaction history to promote upsells and cross-sells based on greater insight. Embracing a CLM-based approach to managing and mining customer data will break any company out of the price-lower-than-competitor cycles to win business.

- Realize CPQ is designed for a specific series of tasks and cannot scale enterprise-wide across all product and channel selling needs. While CPQ excels as a selling orchestration tool across diverse selling channels and selling organizations, it is not designed to scale across PLM and ERP workflows and processes. These are designed to scale across CRM systems, relying on those applications as their systems of record. A CLM system can scale enterprise-wide encompassing the most valuable data in PLM, CRM, and ERP systems, turning any company’s most valuable data into revenue and profit growth.

- Find new ways to monetize the massive amount of data being generated by PLM, ERP, and CRM systems today. It’s time to move beyond the fragmented, often unorganized approach to managing product, manufacturing and customer data and the resulting less-than-optimal decisions. Creating a new system of record that orchestrates the most valuable data your company has into a single, unified system of record will drive greater revenue and profitability.

- Be smarter and stronger by combining Product Release and Operations, so each new product launch succeeds and drives revenue. The tighter the data, systems, processes, and product integrations between these two areas, the higher the probability of sales cycle, revenue and profit growth. Orchestrating Engineering, Configuration Management, and Operations Enablement to shared sales, manufacturing & fulfillment and service goals are key to driving greater revenue growth.

Scaling CLM Insights So The Customer Always Attains Their Goals Is The Secret

Instead of allowing complexity to drive customers away to competitors who are easier to do business with, manufacturers must make complexity work to their advantage by refocusing on the most valuable data in the diverse PLM, ERP and CRM systems they rely on daily. It’s time to revolutionize how these systems are used to put the customer and their unique product configuration and customization requirements first.

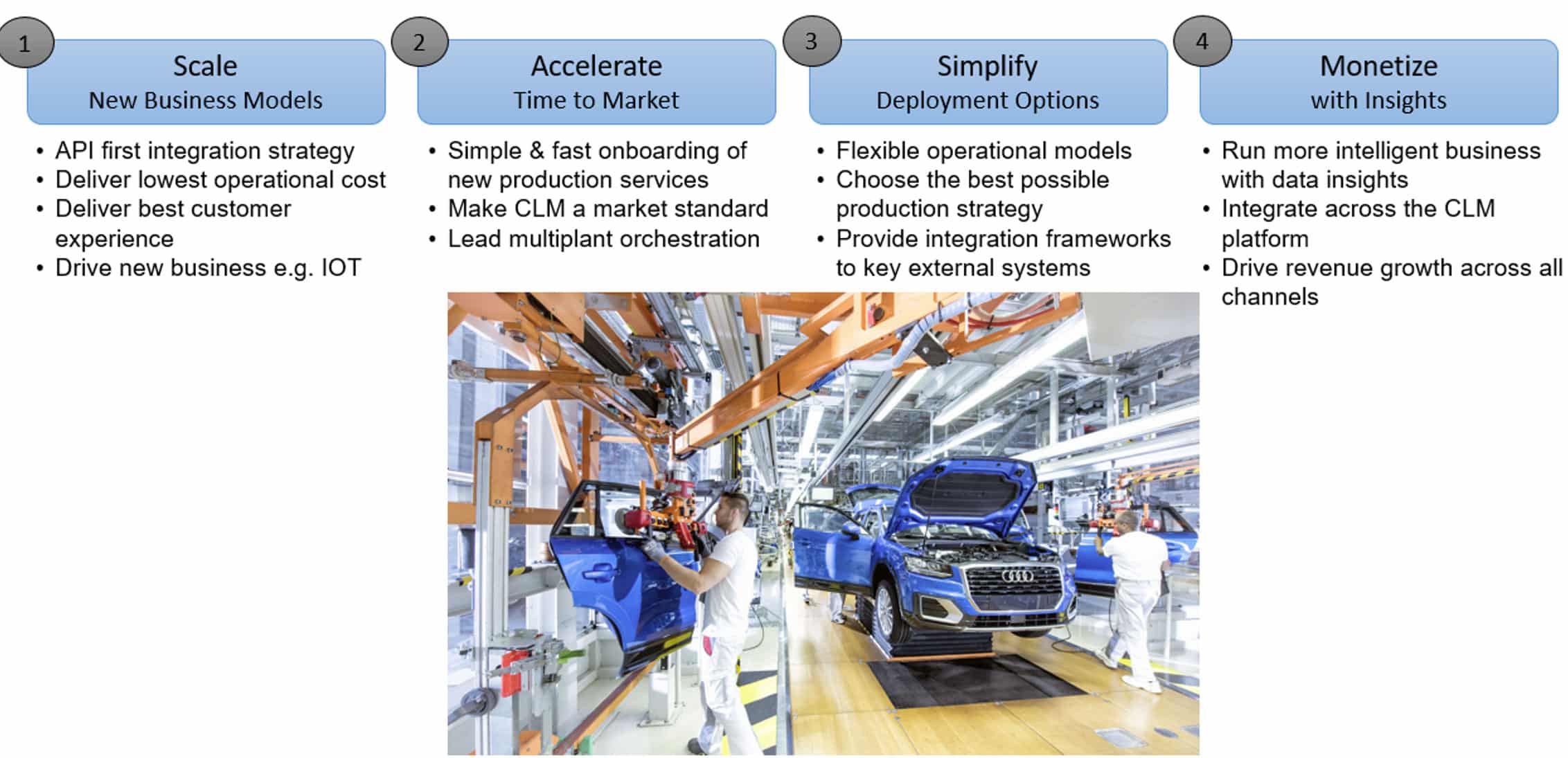

- Scale every aspect of a customer’s experience so they have the greatest opportunity to attain their goals. Designing in excellence begins by choosing to excel at scaling selling, product lifecycle management, and essential manufacturing strategies. Best practices in this area are concentrating cloud-based open architectures that rely on an Application Programming Interface (API)-first strategy that has integration points from the Internet of Things (IoT) integration. A cloud-based CLM architecture is the fastest onramp there is to excel at this vital first step in enabling customers to attain their goals. Once a scalable system of record to support new business models is in place, it’s time to put the system into motion and drive sales. This is followed by accelerating new products to market, driving simplicity into selling and deployment systems, and monetizing the data using variable data. The following graphic provides an overview of how manufacturers can gain competitive strength and revenue gains from being customer-driven.

Scale, Accelerate and Simplify Product Strategies In Response To Customer Requirements

- To answer the question, “Do CLM strategies make a positive impact on growth?” you must start by designing in, from the beginning, analytics and manufacturing intelligence. Getting to the truth of CLM’s contribution to any manufacturing company needs to be based on data. That’s why the manufacturers who are revolutionizing their businesses today are designing in analytics and manufacturing intelligence from the very beginning. CLM systems that capture the most valuable data manufacturers have are already ahead of competitors. By putting this data to work they drive valuable analytical insight and gain valuable manufacturing intelligence learning new ways to excel for customers. Consider the following findings from recent surveys that reflect how manufacturers are looking to revolutionize their operations using analytics:

- 46% of manufacturers agree that implementing and using data analytics is necessary to stay competitive and grow their businesses.

- 69% of decision-makers believe analytics will be crucial for business success in 2020, with 15% considering it crucial today.

- 32% see the potential for big data analytics and Industrial Internet of Things (IIoT) to improve supply chain performance and increase revenue. Manufacturers perceive data analytics as a key component of a successful Industrial Internet of Things (IIoT) strategy across their operations.