Bottom Line

Real-Time Product Collaboration Is Revolutionizing Customer Relationships

Closing the gaps between what sales sells and production can deliver takes more than a sell-side CPQ app. Managing products as platforms is the future, and it’s coming faster than many realize

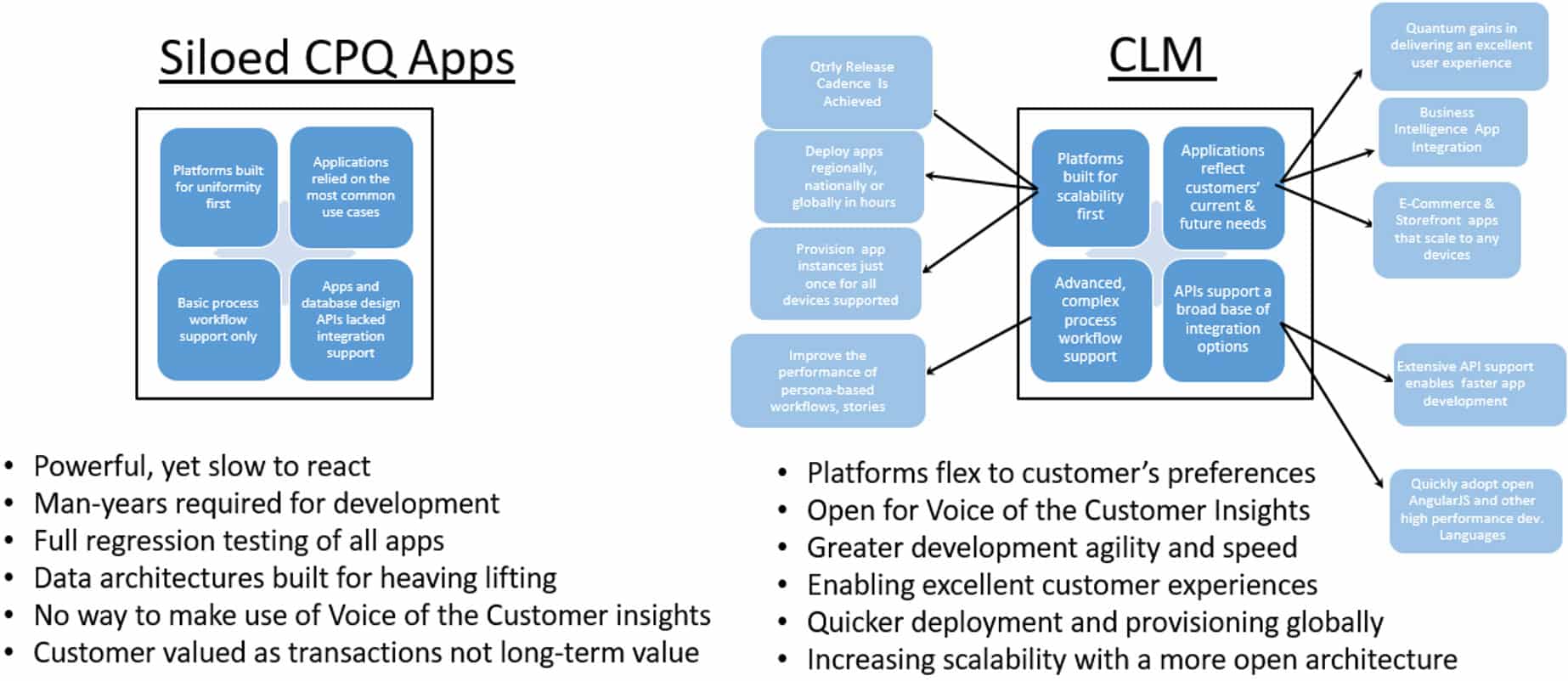

Solving the many disconnects across selling channels and integrating product catalogs, pricing, contracts, and quotes are where CPQ apps excel today. And for all the hype that surrounds CPQ, they still aren’t scaling to be true product platforms. The gap between what sales believe they can sell and what products can deliver has never been bigger, and it’s growing fast. What’s causing the disconnect is the lack of scale CPQ apps have in response to the need to develop products as platforms.